Page 58 - Synthetic Fuels Handbook

P. 58

46 CHAPTER TWO

absorbent is stripped of the gas components (regeneration) and recycled to the absorber.

The process design will vary and, in practice, may employ multiple absorption columns

and multiple regeneration columns.

Amine (olamine) washing of natural gas involves chemical reaction of the amine with

any acid gases with the liberation of an appreciable amount of heat and it is necessary to

compensate for the absorption of heat. Amine derivatives such as monoethanolamine or

ethanolamine (MEA), diethanolamine (DEA), triethanolamine (TEA), methyldiethanol-

amine (MDEA), diisopropanolamine (DIPA), and diglycolamine (DGA) have been used in

commercial applications (Kohl and Riesenfeld, 1985; Speight, 1993; Polasek and Bullin,

1994; Mokhatab et al., 2006; Speight, 2007b).

Processes that use MDEA became popular with the natural gas industry because of its

high selectivity for hydrogen sulfide over carbon dioxide. This high selectivity allows for

a reduced solvent circulation rate, as well as a richer hydrogen sulfide feed to the sulfur

recovery unit. The reaction of MDEA with hydrogen sulfide is almost instantaneous.

However, the reaction of MDEA with carbon dioxide is much slower; the reaction rate of

MDEA with carbon dioxide is slower than that of carbon dioxide with MEA.

Depending upon the application, special solutions such as mixtures of amines; amines

with physical solvents such as sulfolane and piperazine; and amines that have been partially

neutralized with an acid such as phosphoric acid may also be used (Bullin, 2003).

The proper selection of the amine can have a major impact on the performance and cost

of a sweetening unit. However, many factors must be considered when selecting an amine

for a sweetening application (Polasek and Bullin, 1994). Considerations for evaluating an

amine type in gas treating systems are numerous. It is important to consider all aspects of

the amine chemistry and type since the omission of a single issue may lead to operational

issues. While studying each issue, it is important to understand the fundamentals of each

amine solution.

2(RNH ) + H S ↔ (RNH ) S

2 2 3 2

(RNH ) S + H S ↔ 2(RNH )HS

2

3 2

3

2(RNH ) + CO ↔ RNHCOONH R

2

2

3

These reactions are reversible by changing the system temperature. Ethanolamine also

reacts with carbonyl sulfide and carbon disulfide to form heat-stable salts that cannot be

regenerated.

Diethanolamine is a weaker base than ethanolamine and therefore the diethanolamine

system does not typically suffer the same corrosion problems but does reacts with hydrogen

sulfide and carbon dioxide:

2R NH + H S ↔ (R NH ) S

2 2

2

2

2

(R NH ) S + H S ↔ 2(R NH )HS

2

2

2 2

2

2

2R NH + CO ↔ R NCOONH R

2 2 2 2 2

Diethanolamine also removes carbonyl sulfide and carbon disulfide partially as its

regenerable compound with carbonyl sulfide and carbon disulfide without much solution

losses.

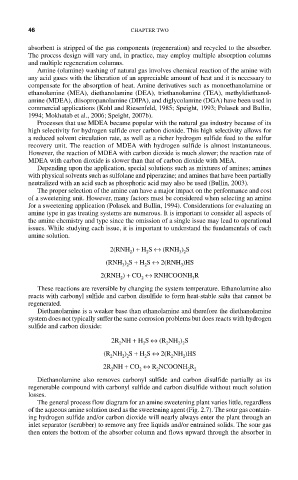

The general process flow diagram for an amine sweetening plant varies little, regardless

of the aqueous amine solution used as the sweetening agent (Fig. 2.7). The sour gas contain-

ing hydrogen sulfide and/or carbon dioxide will nearly always enter the plant through an

inlet separator (scrubber) to remove any free liquids and/or entrained solids. The sour gas

then enters the bottom of the absorber column and flows upward through the absorber in