Page 81 - Synthetic Fuels Handbook

P. 81

68 CHAPTER THREE

ground. The separator may be no more than a large vessel that gives a quieting zone for

gravity separation into three phases: gases, crude oil, and water containing entrained dirt.

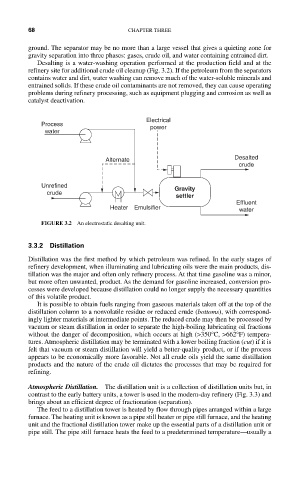

Desalting is a water-washing operation performed at the production field and at the

refinery site for additional crude oil cleanup (Fig. 3.2). If the petroleum from the separators

contains water and dirt, water washing can remove much of the water-soluble minerals and

entrained solids. If these crude oil contaminants are not removed, they can cause operating

problems during refinery processing, such as equipment plugging and corrosion as well as

catalyst deactivation.

Electrical

Process power

water

Alternate Desalted

crude

Unrefined

Gravity

crude

settler

Effluent

Heater Emulsifier water

FIGURE 3.2 An electrostatic desalting unit.

3.3.2 Distillation

Distillation was the first method by which petroleum was refined. In the early stages of

refinery development, when illuminating and lubricating oils were the main products, dis-

tillation was the major and often only refinery process. At that time gasoline was a minor,

but more often unwanted, product. As the demand for gasoline increased, conversion pro-

cesses were developed because distillation could no longer supply the necessary quantities

of this volatile product.

It is possible to obtain fuels ranging from gaseous materials taken off at the top of the

distillation column to a nonvolatile residue or reduced crude (bottoms), with correspond-

ingly lighter materials at intermediate points. The reduced crude may then be processed by

vacuum or steam distillation in order to separate the high-boiling lubricating oil fractions

without the danger of decomposition, which occurs at high (>350°C, >662°F) tempera-

tures. Atmospheric distillation may be terminated with a lower boiling fraction (cut) if it is

felt that vacuum or steam distillation will yield a better-quality product, or if the process

appears to be economically more favorable. Not all crude oils yield the same distillation

products and the nature of the crude oil dictates the processes that may be required for

refining.

Atmospheric Distillation. The distillation unit is a collection of distillation units but, in

contrast to the early battery units, a tower is used in the modern-day refinery (Fig. 3.3) and

brings about an efficient degree of fractionation (separation).

The feed to a distillation tower is heated by flow through pipes arranged within a large

furnace. The heating unit is known as a pipe still heater or pipe still furnace, and the heating

unit and the fractional distillation tower make up the essential parts of a distillation unit or

pipe still. The pipe still furnace heats the feed to a predetermined temperature—usually a