Page 83 - Synthetic Fuels Handbook

P. 83

70 CHAPTER THREE

To vacuum

system

Vacuum tower Vacuum

gas oil

Lubricating oils

Residuum Vacuum

residuum

Furnace

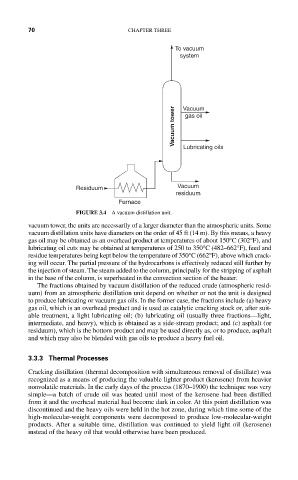

FIGURE 3.4 A vacuum distillation unit.

vacuum tower, the units are necessarily of a larger diameter than the atmospheric units. Some

vacuum distillation units have diameters on the order of 45 ft (14 m). By this means, a heavy

gas oil may be obtained as an overhead product at temperatures of about 150°C (302°F), and

lubricating oil cuts may be obtained at temperatures of 250 to 350°C (482–662°F), feed and

residue temperatures being kept below the temperature of 350°C (662°F), above which crack-

ing will occur. The partial pressure of the hydrocarbons is effectively reduced still further by

the injection of steam. The steam added to the column, principally for the stripping of asphalt

in the base of the column, is superheated in the convection section of the heater.

The fractions obtained by vacuum distillation of the reduced crude (atmospheric resid-

uum) from an atmospheric distillation unit depend on whether or not the unit is designed

to produce lubricating or vacuum gas oils. In the former case, the fractions include (a) heavy

gas oil, which is an overhead product and is used as catalytic cracking stock or, after suit-

able treatment, a light lubricating oil; (b) lubricating oil (usually three fractions—light,

intermediate, and heavy), which is obtained as a side-stream product; and (c) asphalt (or

residuum), which is the bottom product and may be used directly as, or to produce, asphalt

and which may also be blended with gas oils to produce a heavy fuel oil.

3.3.3 Thermal Processes

Cracking distillation (thermal decomposition with simultaneous removal of distillate) was

recognized as a means of producing the valuable lighter product (kerosene) from heavier

nonvolatile materials. In the early days of the process (1870–1900) the technique was very

simple—a batch of crude oil was heated until most of the kerosene had been distilled

from it and the overhead material had become dark in color. At this point distillation was

discontinued and the heavy oils were held in the hot zone, during which time some of the

high-molecular-weight components were decomposed to produce low-molecular-weight

products. After a suitable time, distillation was continued to yield light oil (kerosene)

instead of the heavy oil that would otherwise have been produced.