Page 87 - Synthetic Fuels Handbook

P. 87

74 CHAPTER THREE

Condenser

Fractionator

Coker

gas oil Waste heat

boiler

Slurry

recycle

Quench

water

Feedstock Heater

Reactor Coke

Stripper

Air

compressor

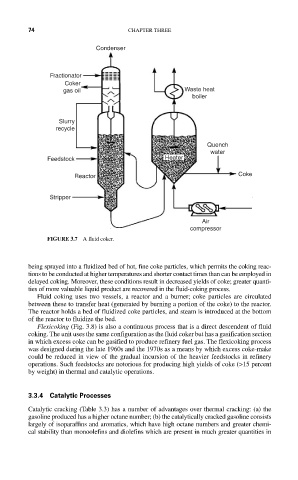

FIGURE 3.7 A fluid coker.

being sprayed into a fluidized bed of hot, fine coke particles, which permits the coking reac-

tions to be conducted at higher temperatures and shorter contact times than can be employed in

delayed coking. Moreover, these conditions result in decreased yields of coke; greater quanti-

ties of more valuable liquid product are recovered in the fluid-coking process.

Fluid coking uses two vessels, a reactor and a burner; coke particles are circulated

between these to transfer heat (generated by burning a portion of the coke) to the reactor.

The reactor holds a bed of fluidized coke particles, and steam is introduced at the bottom

of the reactor to fluidize the bed.

Flexicoking (Fig. 3.8) is also a continuous process that is a direct descendent of fluid

coking. The unit uses the same configuration as the fluid coker but has a gasification section

in which excess coke can be gasified to produce refinery fuel gas. The flexicoking process

was designed during the late 1960s and the 1970s as a means by which excess coke-make

could be reduced in view of the gradual incursion of the heavier feedstocks in refinery

operations. Such feedstocks are notorious for producing high yields of coke (>15 percent

by weight) in thermal and catalytic operations.

3.3.4 Catalytic Processes

Catalytic cracking (Table 3.3) has a number of advantages over thermal cracking: (a) the

gasoline produced has a higher octane number; (b) the catalytically cracked gasoline consists

largely of isoparaffins and aromatics, which have high octane numbers and greater chemi-

cal stability than monoolefins and diolefins which are present in much greater quantities in