Page 91 - Synthetic Fuels Handbook

P. 91

78 CHAPTER THREE

TABLE 3.4 Summary of Hydrocracking Process Operations

Conditions

Solid acid catalyst (silica-alumina with rare earth metals, various other options)

Temperature: 260–450°C (500–842°F) (solid/liquid contact)

Pressure: 1,000–6,000 psi hydrogen

Frequent catalysts renewal for heavier feedstocks

Gas oil: catalyst life up to 3 years

Heavy oil/tar sand bitumen: catalyst life less than 1 year

Feedstocks

Refractory (aromatic) streams

Coker oils

Cycle oils

Gas oils

Residua (as a full hydrocracking or hydrotreating option)

In some cases, asphaltic constituents (S, N, and metals) removed by deasphalting

Products

Lower molecular weight paraffins

Some methane, ethane, propane, and butane

Hydrocarbon distillates (full range depending on the feedstock)

Residual tar (recycle)

Contaminants (asphaltic constituents) deposited on the catalyst as coke or metals

Variations

Fixed bed (suitable for liquid feedstocks

Ebullating bed (suitable for heavy feedstocks)

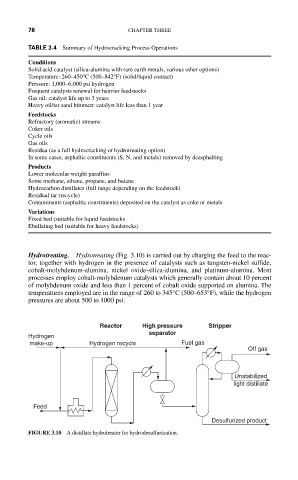

Hydrotreating. Hydrotreating (Fig. 3.10) is carried out by charging the feed to the reac-

tor, together with hydrogen in the presence of catalysts such as tungsten-nickel sulfide,

cobalt-molybdenum-alumina, nickel oxide-silica-alumina, and platinum-alumina. Most

processes employ cobalt-molybdenum catalysts which generally contain about 10 percent

of molybdenum oxide and less than 1 percent of cobalt oxide supported on alumina. The

temperatures employed are in the range of 260 to 345°C (500–653°F), while the hydrogen

pressures are about 500 to 1000 psi.

Reactor High pressure Stripper

separator

Hydrogen

make-up Hydrogen recycle Fuel gas

Off gas

Unstabilized

light distillate

Feed

Desulfurized product

FIGURE 3.10 A distillate hydrotreater for hydrodesulfurization.