Page 94 - Synthetic Fuels Handbook

P. 94

FUELS FROM PETROLEUM AND HEAVY OIL 81

reforming produces reformate with octane numbers on the order of 90 to 95. Catalytic

reforming is conducted in the presence of hydrogen over hydrogenation-dehydrogenation

catalysts, which may be supported on alumina or silica-alumina. Depending on the catalyst,

a definite sequence of reactions takes place, involving structural changes in the feedstock.

This more modern concept actually rendered thermal reforming somewhat obsolescent.

The commercial processes available for use can be broadly classified as the moving

bed, fluid bed, and fixed bed types. The fluid bed and moving bed processes used mixed

nonprecious metal oxide catalysts in units equipped with separate regeneration facilities.

Fixed bed processes use predominantly platinum-containing catalysts in units equipped for

cycle, occasional, or no regeneration.

Catalytic reformer feeds are saturated (i.e., not olefinic) materials; in the majority of

cases that feed may be a straight-run naphtha but other by-product low-octane naphtha

(e.g., coker naphtha) can be processed after treatment to remove olefins and other con-

taminants. Hydrocracker naphtha that contains substantial quantities of naphthenes is also

a suitable feed.

Dehydrogenation is a main chemical reaction in catalytic reforming and hydrogen gas

is consequently produced in large quantities. The hydrogen is recycled though the reactors

where the reforming takes place to provide the atmosphere necessary for the chemical

reactions and also prevents the carbon from being deposited on the catalyst, thus extend-

ing its operating life. An excess of hydrogen above whatever is consumed in the process is

produced, and, as a result, catalytic reforming processes are unique in that they are the only

petroleum refinery processes to produce hydrogen as a by-product.

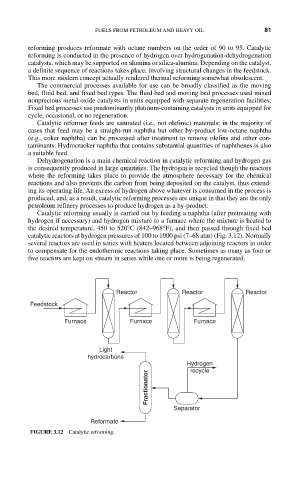

Catalytic reforming usually is carried out by feeding a naphtha (after pretreating with

hydrogen if necessary) and hydrogen mixture to a furnace where the mixture is heated to

the desired temperature, 450 to 520°C (842–968°F), and then passed through fixed bed

catalytic reactors at hydrogen pressures of 100 to 1000 psi (7–68 atm) (Fig. 3.12). Normally

several reactors are used in series with heaters located between adjoining reactors in order

to compensate for the endothermic reactions taking place. Sometimes as many as four or

five reactors are kept on stream in series while one or more is being regenerated.

Reactor Reactor Reactor

Feedstock

Furnace Furnace Furnace

Light

hydrocarbons

Hydrogen

recycle

Fractionator

Separator

Reformate

FIGURE 3.12 Catalytic reforming.