Page 97 - Synthetic Fuels Handbook

P. 97

84 CHAPTER THREE

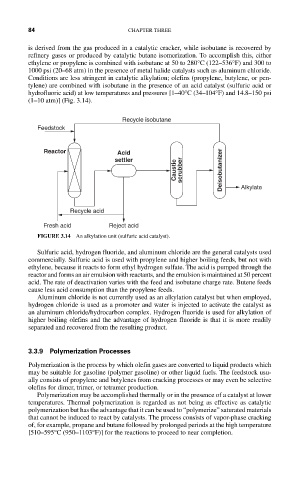

is derived from the gas produced in a catalytic cracker, while isobutane is recovered by

refinery gases or produced by catalytic butane isomerization. To accomplish this, either

ethylene or propylene is combined with isobutane at 50 to 280°C (122–536°F) and 300 to

1000 psi (20–68 atm) in the presence of metal halide catalysts such as aluminum chloride.

Conditions are less stringent in catalytic alkylation; olefins (propylene, butylene, or pen-

tylene) are combined with isobutane in the presence of an acid catalyst (sulfuric acid or

hydrofluoric acid) at low temperatures and pressures [1–40°C (34–104°F) and 14.8–150 psi

(1–10 atm)] (Fig. 3.14).

Recycle isobutane

Feedstock

Reactor Acid

settler

Caustic scrubber Deisobutanizer Alkylate

Recycle acid

Fresh acid Reject acid

FIGURE 3.14 An alkylation unit (sulfuric acid catalyst).

Sulfuric acid, hydrogen fluoride, and aluminum chloride are the general catalysts used

commercially. Sulfuric acid is used with propylene and higher boiling feeds, but not with

ethylene, because it reacts to form ethyl hydrogen sulfate. The acid is pumped through the

reactor and forms an air emulsion with reactants, and the emulsion is maintained at 50 percent

acid. The rate of deactivation varies with the feed and isobutane charge rate. Butene feeds

cause less acid consumption than the propylene feeds.

Aluminum chloride is not currently used as an alkylation catalyst but when employed,

hydrogen chloride is used as a promoter and water is injected to activate the catalyst as

an aluminum chloride/hydrocarbon complex. Hydrogen fluoride is used for alkylation of

higher boiling olefins and the advantage of hydrogen fluoride is that it is more readily

separated and recovered from the resulting product.

3.3.9 Polymerization Processes

Polymerization is the process by which olefin gases are converted to liquid products which

may be suitable for gasoline (polymer gasoline) or other liquid fuels. The feedstock usu-

ally consists of propylene and butylenes from cracking processes or may even be selective

olefins for dimer, trimer, or tetramer production.

Polymerization may be accomplished thermally or in the presence of a catalyst at lower

temperatures. Thermal polymerization is regarded as not being as effective as catalytic

polymerization but has the advantage that it can be used to “polymerize” saturated materials

that cannot be induced to react by catalysts. The process consists of vapor-phase cracking

of, for example, propane and butane followed by prolonged periods at the high temperature

[510–595°C (950–1103°F)] for the reactions to proceed to near completion.