Page 96 - Synthetic Fuels Handbook

P. 96

FUELS FROM PETROLEUM AND HEAVY OIL 83

(aluminum chloride, noble metals) processes. Natural gasoline or light straight-run gaso-

line can provide feed by first fractionating as a preparatory step. High volumetric yields

(>95 percent) and 40 to 60 percent conversion per pass are characteristic of the isomeriza-

tion reaction.

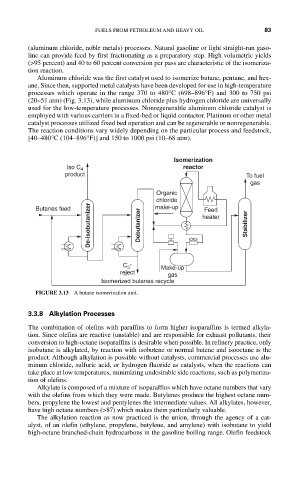

Aluminum chloride was the first catalyst used to isomerize butane, pentane, and hex-

ane. Since then, supported metal catalysts have been developed for use in high-temperature

processes which operate in the range 370 to 480°C (698–896°F) and 300 to 750 psi

(20–51 atm) (Fig. 3.13), while aluminum chloride plus hydrogen chloride are universally

used for the low-temperature processes. Nonregenerable aluminum chloride catalyst is

employed with various carriers in a fixed-bed or liquid contactor. Platinum or other metal

catalyst processes utilized fixed bed operation and can be regenerable or nonregenerable.

The reaction conditions vary widely depending on the particular process and feedstock,

[40–480°C (104–896°F)] and 150 to 1000 psi (10–68 atm).

Isomerization

Iso C 4 reactor

product To fuel

gas

Organic

chloride

De-isobutanizer Debutanizer Stabilizer

Butanes feed make-up heater

Feed

C + Make-up

5

reject gas

Isomerized butanes recycle

FIGURE 3.13 A butane isomerization unit.

3.3.8 Alkylation Processes

The combination of olefins with paraffins to form higher isoparaffins is termed alkyla-

tion. Since olefins are reactive (unstable) and are responsible for exhaust pollutants, their

conversion to high-octane isoparaffins is desirable when possible. In refinery practice, only

isobutane is alkylated, by reaction with isobutene or normal butene and isooctane is the

product. Although alkylation is possible without catalysts, commercial processes use alu-

minum chloride, sulfuric acid, or hydrogen fluoride as catalysts, when the reactions can

take place at low temperatures, minimizing undesirable side reactions, such as polymeriza-

tion of olefins.

Alkylate is composed of a mixture of isoparaffins which have octane numbers that vary

with the olefins from which they were made. Butylenes produce the highest octane num-

bers, propylene the lowest and pentylenes the intermediate values. All alkylates, however,

have high octane numbers (>87) which makes them particularly valuable.

The alkylation reaction as now practiced is the union, through the agency of a cat-

alyst, of an olefin (ethylene, propylene, butylene, and amylene) with isobutane to yield

high-octane branched-chain hydrocarbons in the gasoline boiling range. Olefin feedstock