Page 98 - Synthetic Fuels Handbook

P. 98

FUELS FROM PETROLEUM AND HEAVY OIL 85

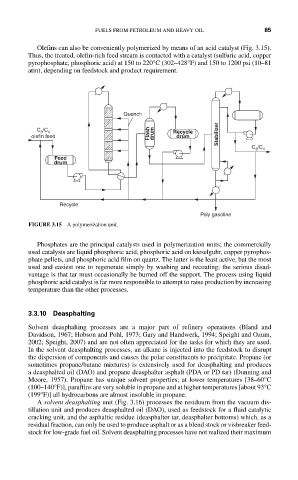

Olefins can also be conveniently polymerized by means of an acid catalyst (Fig. 3.15).

Thus, the treated, olefin-rich feed stream is contacted with a catalyst (sulfuric acid, copper

pyrophosphate, phosphoric acid) at 150 to 220°C (302–428°F) and 150 to 1200 psi (10–81

atm), depending on feedstock and product requirement.

Quench

C /C 4 Recycle

3

olefin feed Flash drum drum Stabilizer

C /C 4

3

Feed

drum

Recycle

Poly gasoline

FIGURE 3.15 A polymerization unit.

Phosphates are the principal catalysts used in polymerization units; the commercially

used catalysts are liquid phosphoric acid, phosphoric acid on kieselguhr, copper pyrophos-

phate pellets, and phosphoric acid film on quartz. The latter is the least active, but the most

used and easiest one to regenerate simply by washing and recoating; the serious disad-

vantage is that tar must occasionally be burned off the support. The process using liquid

phosphoric acid catalyst is far more responsible to attempt to raise production by increasing

temperature than the other processes.

3.3.10 Deasphalting

Solvent deasphalting processes are a major part of refinery operations (Bland and

Davidson, 1967; Hobson and Pohl, 1973; Gary and Handwerk, 1994; Speight and Ozum,

2002; Speight, 2007) and are not often appreciated for the tasks for which they are used.

In the solvent deasphalting processes, an alkane is injected into the feedstock to disrupt

the dispersion of components and causes the polar constituents to precipitate. Propane (or

sometimes propane/butane mixtures) is extensively used for deasphalting and produces

a deasphalted oil (DAO) and propane deasphalter asphalt (PDA or PD tar) (Dunning and

Moore, 1957). Propane has unique solvent properties; at lower temperatures [38–60°C

(100–140°F)], paraffins are very soluble in propane and at higher temperatures [about 93°C

(199°F)] all hydrocarbons are almost insoluble in propane.

A solvent deasphalting unit (Fig. 3.16) processes the residuum from the vacuum dis-

tillation unit and produces deasphalted oil (DAO), used as feedstock for a fluid catalytic

cracking unit, and the asphaltic residue (deasphalter tar, deasphalter bottoms) which, as a

residual fraction, can only be used to produce asphalt or as a blend stock or visbreaker feed-

stock for low-grade fuel oil. Solvent deasphalting processes have not realized their maximum