Page 99 - Synthetic Fuels Handbook

P. 99

86 CHAPTER THREE

Solvent

to

recovery

Steam Steam

Steam

Condensate

Deasphalter

charge Solvent

Deasphalter to

recovery

Solvent

stripper

Steam

Recovered

solvent

Deasphalted

oil

To asphalt

recovery

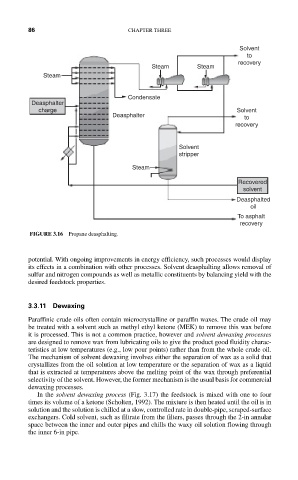

FIGURE 3.16 Propane deasphalting.

potential. With ongoing improvements in energy efficiency, such processes would display

its effects in a combination with other processes. Solvent deasphalting allows removal of

sulfur and nitrogen compounds as well as metallic constituents by balancing yield with the

desired feedstock properties.

3.3.11 Dewaxing

Paraffinic crude oils often contain microcrystalline or paraffin waxes. The crude oil may

be treated with a solvent such as methyl ethyl ketone (MEK) to remove this wax before

it is processed. This is not a common practice, however and solvent dewaxing processes

are designed to remove wax from lubricating oils to give the product good fluidity charac-

teristics at low temperatures (e.g., low pour points) rather than from the whole crude oil.

The mechanism of solvent dewaxing involves either the separation of wax as a solid that

crystallizes from the oil solution at low temperature or the separation of wax as a liquid

that is extracted at temperatures above the melting point of the wax through preferential

selectivity of the solvent. However, the former mechanism is the usual basis for commercial

dewaxing processes.

In the solvent dewaxing process (Fig. 3.17) the feedstock is mixed with one to four

times its volume of a ketone (Scholten, 1992). The mixture is then heated until the oil is in

solution and the solution is chilled at a slow, controlled rate in double-pipe, scraped-surface

exchangers. Cold solvent, such as filtrate from the filters, passes through the 2-in annular

space between the inner and outer pipes and chills the waxy oil solution flowing through

the inner 6-in pipe.