Page 100 - Synthetic Fuels Handbook

P. 100

FUELS FROM PETROLEUM AND HEAVY OIL 87

Solvent

Wash

solvent

O

Slack wax evaporator

Heater

Rotary filter

Dewaxed oil evaporator

Chiller

Heat exchanger

Steam heater Heater

Feed Dewaxed oil Stack wax

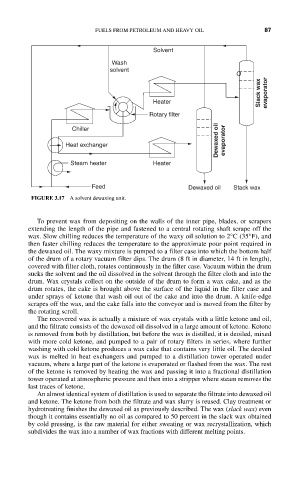

FIGURE 3.17 A solvent dewaxing unit.

To prevent wax from depositing on the walls of the inner pipe, blades, or scrapers

extending the length of the pipe and fastened to a central rotating shaft scrape off the

wax. Slow chilling reduces the temperature of the waxy oil solution to 2°C (35°F), and

then faster chilling reduces the temperature to the approximate pour point required in

the dewaxed oil. The waxy mixture is pumped to a filter case into which the bottom half

of the drum of a rotary vacuum filter dips. The drum (8 ft in diameter, 14 ft in length),

covered with filter cloth, rotates continuously in the filter case. Vacuum within the drum

sucks the solvent and the oil dissolved in the solvent through the filter cloth and into the

drum. Wax crystals collect on the outside of the drum to form a wax cake, and as the

drum rotates, the cake is brought above the surface of the liquid in the filter case and

under sprays of ketone that wash oil out of the cake and into the drum. A knife-edge

scrapes off the wax, and the cake falls into the conveyor and is moved from the filter by

the rotating scroll.

The recovered wax is actually a mixture of wax crystals with a little ketone and oil,

and the filtrate consists of the dewaxed oil dissolved in a large amount of ketone. Ketone

is removed from both by distillation, but before the wax is distilled, it is deoiled, mixed

with more cold ketone, and pumped to a pair of rotary filters in series, where further

washing with cold ketone produces a wax cake that contains very little oil. The deoiled

wax is melted in heat exchangers and pumped to a distillation tower operated under

vacuum, where a large part of the ketone is evaporated or flashed from the wax. The rest

of the ketone is removed by heating the wax and passing it into a fractional distillation

tower operated at atmospheric pressure and then into a stripper where steam removes the

last traces of ketone.

An almost identical system of distillation is used to separate the filtrate into dewaxed oil

and ketone. The ketone from both the filtrate and wax slurry is reused. Clay treatment or

hydrotreating finishes the dewaxed oil as previously described. The wax (slack wax) even

though it contains essentially no oil as compared to 50 percent in the slack wax obtained

by cold pressing, is the raw material for either sweating or wax recrystallization, which

subdivides the wax into a number of wax fractions with different melting points.