Page 92 - Synthetic Fuels Handbook

P. 92

FUELS FROM PETROLEUM AND HEAVY OIL 79

Hydrocracking. Hydrocracking is similar to catalytic cracking, with hydrogenation

superimposed and with the reactions taking place either simultaneously or sequentially.

Hydrocracking was initially used to upgrade low-value distillate feedstocks, such as cycle

oils (high aromatic products from a catalytic cracker which usually are not recycled to

extinction for economic reasons), thermal and coker gas oils, and heavy-cracked and

straight-run naphtha. These feedstocks are difficult to process by either catalytic cracking

or reforming, since they are characterized usually by a high polycyclic aromatic content

and/or by high concentrations of the two principal catalyst poisons—sulfur and nitrogen

compounds.

A comparison of hydrocracking with hydrotreating is useful in assessing the parts played

by these two processes in refinery operations. Hydrotreating of distillates may be defined

simply as the removal of nitrogen—sulfur and oxygen-containing compounds by selective

hydrogenation. The hydrotreating catalysts are usually cobalt plus molybdenum or nickel

plus molybdenum (in the sulfide) form impregnated on an alumina base. The hydrotreated

operating conditions are such that appreciable hydrogenation of aromatics will not occur—

1000 to 2000 psi hydrogen and about 370°C (698°F). The desulfurization reactions are

usually accompanied by small amounts of hydrogenation and hydrocracking.

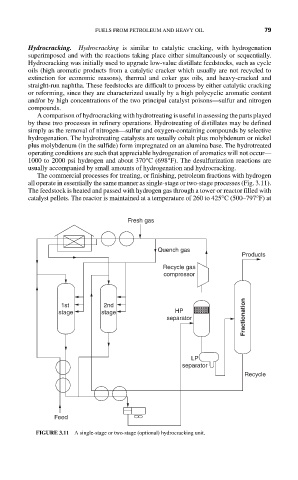

The commercial processes for treating, or finishing, petroleum fractions with hydrogen

all operate in essentially the same manner as single-stage or two-stage processes (Fig. 3.11).

The feedstock is heated and passed with hydrogen gas through a tower or reactor filled with

catalyst pellets. The reactor is maintained at a temperature of 260 to 425°C (500–797°F) at

Fresh gas

Quench gas

Products

Recycle gas

compressor

Fractionation

1st 2nd

stage stage HP

separator

LP

separator

Recycle

Feed

FIGURE 3.11 A single-stage or two-stage (optional) hydrocracking unit.