Page 89 - Synthetic Fuels Handbook

P. 89

76 CHAPTER THREE

thermally cracked gasoline. Substantial quantities of olefinic gases suitable for poly-

mer gasoline manufacture and smaller quantities of methane, ethane, and ethylene are

produced by catalytic cracking. Sulfur compounds are changed in such a way that the

sulfur content of catalytically cracked gasoline is lower than in thermally cracked gaso-

line. Catalytic cracking produces less heavy residual or tar and more of the useful gas

oils than does thermal cracking. The process has considerable flexibility, permitting the

manufacture of both motor and aviation gasoline and a variation in the gas oil yield to

meet changes in the fuel oil market.

The several processes currently employed in catalytic cracking differ mainly in the

method of catalyst handling, although there is overlap with regard to catalyst type and the

nature of the products.

The catalyst, which may be an activated natural or synthetic material, is employed

in bead, pellet, or microspherical form and can be used as a fixed bed, moving bed, or

fluid bed. The fixed bed process was the first process to be used commercially and uses

a static bed of catalyst in several reactors, which allows a continuous flow of feedstock

to be maintained. Thus, the cycle of operations consists of (a) flow of feedstock through

the catalyst bed, (b) discontinuance of feedstock flow and removal of coke from the

catalyst by burning, and (c) insertion of the reactor on stream. The moving bed process

uses a reaction vessel (in which cracking takes place) and a kiln (in which the spent

catalyst is regenerated) and catalyst movement between the vessels is provided by

various means.

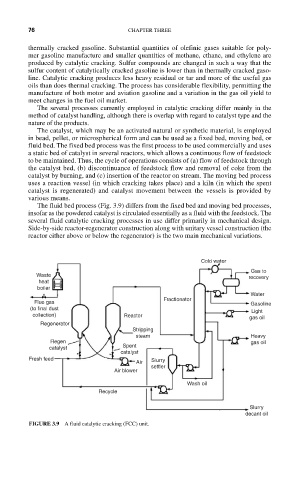

The fluid bed process (Fig. 3.9) differs from the fixed bed and moving bed processes,

insofar as the powdered catalyst is circulated essentially as a fluid with the feedstock. The

several fluid catalytic cracking processes in use differ primarily in mechanical design.

Side-by-side reactor-regenerator construction along with unitary vessel construction (the

reactor either above or below the regenerator) is the two main mechanical variations.

Cold water

Gas to

Waste

recovery

heat

boiler

Water

Fractionator

Flue gas Gasoline

(to final dust Light

collection) Reactor

gas oil

Regenerator

Stripping

steam Heavy

Regen gas oil

Spent

catalyst

catalyst

Fresh feed Slurry

Air

settler

Air blower

Wash oil

Recycle

Slurry

decant oil

FIGURE 3.9 A fluid catalytic cracking (FCC) unit.