Page 86 - Synthetic Fuels Handbook

P. 86

FUELS FROM PETROLEUM AND HEAVY OIL 73

After a gap of several years, the recovery of heavy oils either through secondary recov-

ery techniques from oil sand formations caused a renewal of interest in these feedstocks in

the 1960s and, henceforth, for coking operations. Furthermore, the increasing attention paid

to reducing atmospheric pollution has also served to direct some attention to coking, since

the process not only concentrates pollutants such as feedstock sulfur in the coke, but also

can usually yield volatile products that can be conveniently desulfurized.

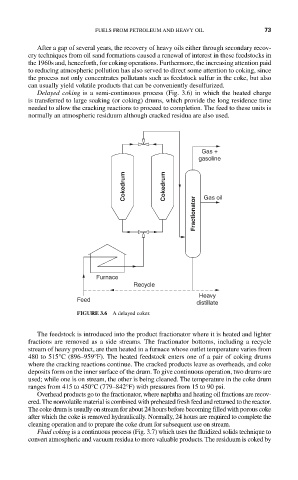

Delayed coking is a semi-continuous process (Fig. 3.6) in which the heated charge

is transferred to large soaking (or coking) drums, which provide the long residence time

needed to allow the cracking reactions to proceed to completion. The feed to these units is

normally an atmospheric residuum although cracked residua are also used.

Gas +

gasoline

Cokedrum Cokedrum Gas oil

Fractionator

Furnace

Recycle

Heavy

Feed

distillate

FIGURE 3.6 A delayed coker.

The feedstock is introduced into the product fractionator where it is heated and lighter

fractions are removed as a side streams. The fractionator bottoms, including a recycle

stream of heavy product, are then heated in a furnace whose outlet temperature varies from

480 to 515°C (896–959°F). The heated feedstock enters one of a pair of coking drums

where the cracking reactions continue. The cracked products leave as overheads, and coke

deposits form on the inner surface of the drum. To give continuous operation, two drums are

used; while one is on stream, the other is being cleaned. The temperature in the coke drum

ranges from 415 to 450°C (779–842°F) with pressures from 15 to 90 psi.

Overhead products go to the fractionator, where naphtha and heating oil fractions are recov-

ered. The nonvolatile material is combined with preheated fresh feed and returned to the reactor.

The coke drum is usually on stream for about 24 hours before becoming filled with porous coke

after which the coke is removed hydraulically. Normally, 24 hours are required to complete the

cleaning operation and to prepare the coke drum for subsequent use on stream.

Fluid coking is a continuous process (Fig. 3.7) which uses the fluidized solids technique to

convert atmospheric and vacuum residua to more valuable products. The residuum is coked by