Page 85 - Synthetic Fuels Handbook

P. 85

72 CHAPTER THREE

Gas +

gasoline

Fractionator

Quench Gas oil

Internals

for reducing

Soaker

backmixing

Cracked or

Furnace visbroken residue

Feed

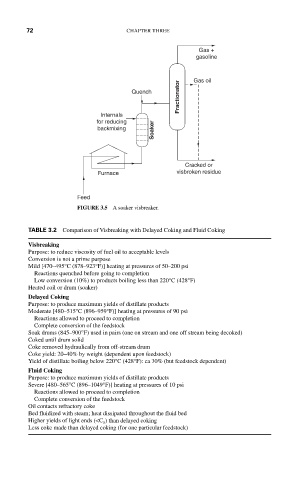

FIGURE 3.5 A soaker visbreaker.

TABLE 3.2 Comparison of Visbreaking with Delayed Coking and Fluid Coking

Visbreaking

Purpose: to reduce viscosity of fuel oil to acceptable levels

Conversion is not a prime purpose

Mild [470–495°C (878–923°F)] heating at pressures of 50–200 psi

Reactions quenched before going to completion

Low conversion (10%) to products boiling less than 220°C (428°F)

Heated coil or drum (soaker)

Delayed Coking

Purpose: to produce maximum yields of distillate products

Moderate [480–515°C (896–959°F)] heating at pressures of 90 psi

Reactions allowed to proceed to completion

Complete conversion of the feedstock

Soak drums (845–900°F) used in pairs (one on stream and one off stream being decoked)

Coked until drum solid

Coke removed hydraulically from off-stream drum

Coke yield: 20–40% by weight (dependent upon feedstock)

Yield of distillate boiling below 220°C (428°F): ca 30% (but feedstock dependent)

Fluid Coking

Purpose: to produce maximum yields of distillate products

Severe [480–565°C (896–1049°F)] heating at pressures of 10 psi

Reactions allowed to proceed to completion

Complete conversion of the feedstock

Oil contacts refractory coke

Bed fluidized with steam; heat dissipated throughout the fluid bed

Higher yields of light ends (<C ) than delayed coking

5

Less coke made than delayed coking (for one particular feedstock)