Page 88 - Synthetic Fuels Handbook

P. 88

FUELS FROM PETROLEUM AND HEAVY OIL 75

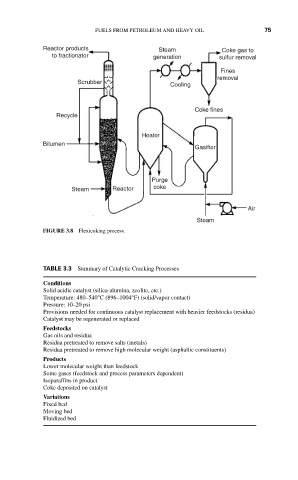

Reactor products Steam Coke gas to

to fractionator generation sulfur removal

Fines

removal

Scrubber

Cooling

Coke fines

Recycle

Heater

Bitumen

Gasifier

Purge

Steam Reactor coke

Air

Steam

FIGURE 3.8 Flexicoking process.

TABLE 3.3 Summary of Catalytic Cracking Processes

Conditions

Solid acidic catalyst (silica-alumina, zeolite, etc.)

Temperature: 480–540°C (896–1004°F) (solid/vapor contact)

Pressure: 10–20 psi

Provisions needed for continuous catalyst replacement with heavier feedstocks (residua)

Catalyst may be regenerated or replaced

Feedstocks

Gas oils and residua

Residua pretreated to remove salts (metals)

Residua pretreated to remove high molecular weight (asphaltic constituents)

Products

Lower molecular weight than feedstock

Some gases (feedstock and process parameters dependent)

Isoparaffins in product

Coke deposited on catalyst

Variations

Fixed bed

Moving bed

Fluidized bed