Page 188 - TPM A Route to World-Class Performance

P. 188

Managing the TPM journey

8.1 Future vision, planning and control

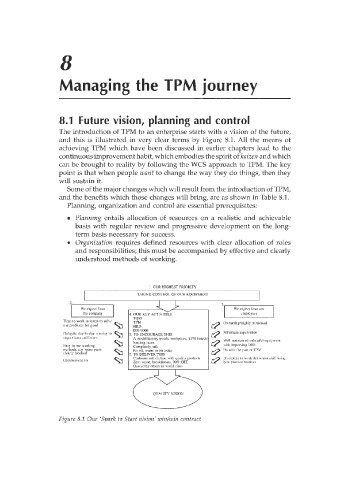

The introduction of TPM to an enterprise starts with a vision of the future,

and this is illustrated in very clear terms by Figure 8.1. All the means of

achieving TPM which have been discussed in earlier chapters lead to the

continuous improvement habit, which embodies the spirit of kuizen and which

can be brought to reality by following the WCS approach to TPM. The key

point is that when people want to change the way they do things, then they

will sustain it.

Some of the major changes which will result from the introduction of TPM,

and the benefits which those changes will bring, are as shown in Table 8.1.

Planning, organization and control are essential prerequisites:

Plannzng entails allocation of resources on a realistic and achievable

basis with regular review and progressive development on the long-

term basis necessary for success.

0 Organization requires defined resources with clear allocation of roles

and responsibilities; this must be accompanied by effective and clearly

understood methods of working.

1. OUR HIGHEST PRIORITY

I TAKING CONTROL OF OUR EQUIPMENT I

I

2.

employees

the company we expect from our

Time to work in teams to solve Q Ownershiplhighly motivated

our problems far good

Delegate day-to-day running to cr Q Minimum supervision

supervision and beloa Well maintained colourful equipment

Easy to use working % Completely safe @ with improving OEE

methods, e.g spare puts No 011, water or air leaks Q Proud to be part of TPM

clearly labelled cr 6. TO DELIVER THIS

Communication cr Customer satisfaction with quality products Discipline to work the whole shift using

best practice routines

Zero waste, breakdowns, 90% OEE

Ouoted bv others as wdd class

Figure 8.1 Our ‘Spark to Start vision’ win/win contract