Page 192 - TPM A Route to World-Class Performance

P. 192

Managing the TPM journey 169

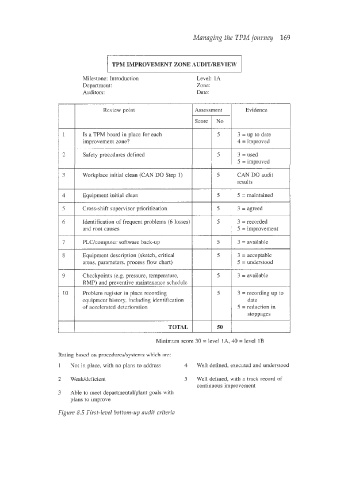

1 TPM IMPROVEMENT ZONE AUDITlREVIEW I

Milestone: Introduction Level: 1A

Department: Zone:

Auditors: Date:

Review point Assessment Evidence

-

Score No

Is a TPM board in place for each 5 3 = up to date

improvement zone? 4 = improved

~

Safety procedures defined 5 3 = used

5 = improved

Workplace initial clean (CAN DO Step 1) 5 CAN DO audit

results

Equipment initial clean 5 5 = maintained

Cross-shift supervisor prioritization 5 3 = agreed

Identification of frequent problems (6 losses) 5 3 = recorded

and root causes 5 = improvement

-

PLChomputer software back-up 5 3 = available

Equipment description (sketch, critical 5 3 = acceptable

areas, parameters. process flow chart) 5 = understood

Checkpoints (e.g. pressure, temperature, 5 3 = available

RMP) and preventive maintenance schedule

Problem register in place recording 5 3 = recording up to

equipment history, including identification date

of accelerated deterioration 5 = reduction in

stoppages

TOTAL I 50

Minimum score 30 = level 1A, 40 = level 1B

Rating based on procedureskystems which are:

1 Not in place, with no plans to address 4 Well defined, executed and understood

2 Weakldeficient 5 Well defined, with a track record of

continuous improvement

3 Able to meet departmentaUplant goals with

plans to improve

Figure 8.5 First-level bottom-up audit criteria