Page 67 - TPM A Route to World-Class Performance

P. 67

48 TPM-A Route to World-Class Performance

TPM is about striving for:

0 zero accidents

0 zero breakdowns

zero defects

zero dust and dirt

3.7 What is the TPM improvement plan?

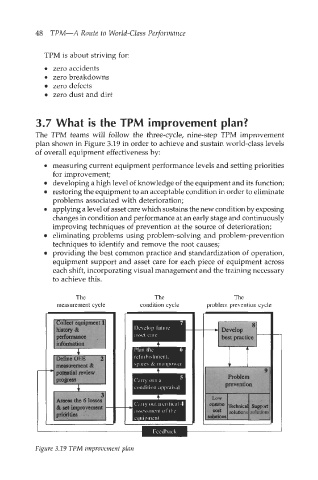

The TPM teams will follow the three-cycle, nine-step TPM improvement

plan shown in Figure 3.19 in order to achieve and sustain world-class levels

of overall equipment effectiveness by:

0 measuring current equipment performance levels and setting priorities

for improvement;

developing a high level of knowledge of the equipment and its function;

restoring the equipment to an acceptable condition in order to eliminate

problems associated with deterioration;

0 applying a level of asset care which sustains the new condition by exposing

changes in condition and performance at an early stage and continuously

improving techniques of prevention at the source of deterioration;

eliminating problems using problem-solving and problem-prevention

techniques to identify and remove the root causes;

providing the best common practice and standardization of operation,

equipment support and asset care for each piece of equipment across

each shift, incorporating visual management and the training necessary

to achieve this.

The The The

measurement cycle condition cycle problem prevention cycle

I

1

Figure 3.19 TPM improvement plan