Page 70 - TPM A Route to World-Class Performance

P. 70

The top-down and bottom-up realities of TPM 51

cause problems which can be prevented (the four Ps) because they are to do

with materials, machines, mechanisms and manpower (the four Ms).

This is the acid test of the TPM pilot@) since the teams are trained, encouraged

and motivated to resolve (once and for all) the six losses which work against

the achievement of world-class levels of overall equipment effectiveness.

These problem-solving opportunities can usually be classified as:

0 operational problems/improvements involving no cost or low cost and

low risk solutions;

technical problems/improvements, often involving the key contacts and

also some cost and, hence, risk;

0 support services and/or support equipment problems/improvements

which can involve the key contacts and some low cost but low risk.

Obviously the elimination of problems needs to be developed into the best

practice routines, the impact of which will feed back into an improved OEE

figure.

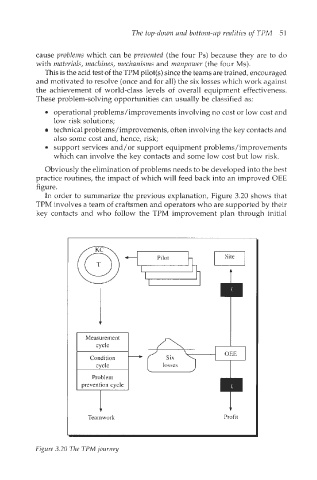

In order to summarize the previous explanation, Figure 3.20 shows that

TPM involves a team of craftsmen and operators who are supported by their

key contacts and who follow the TPM improvement plan through initial

t

U

Site

Measurement

OEE

Condition Six

losses

Problem

Teamwork Profit

Figure 3.20 The TPM journey