Page 198 - TPM A Route to World-Class Performance

P. 198

Managing the TPM journey 175

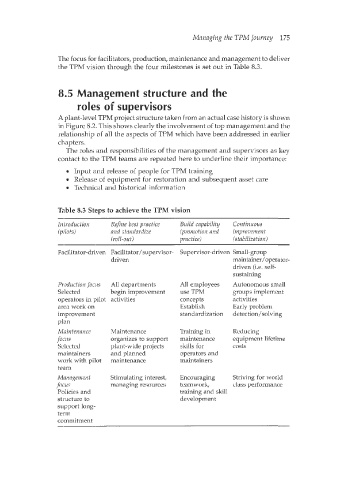

The focus for facilitators, production, maintenance and management to deliver

the TPM vision through the four milestones is set out in Table 8.3.

8.5 Management structure and the

roles of supervisors

A plant-level TPM project structure taken from an actual case history is shown

in Figure 8.2. This shows clearly the involvement of top management and the

relationship of all the aspects of TPM which have been addressed in earlier

chapters.

The roles and responsibilities of the management and supervisors as key

contact to the TPM teams are repeated here to underline their importance:

0 Input and release of people for TPM training

o Release of equipment for restoration and subsequent asset care

0 Technical and historical information

Table 8.3 Steps to achieve the TPM vision

Introduction Refine best practice Build capability Continuous

(pilots) and standardize (promotion and improvement

(roll-out) practice) (stabilization)

Facilitator-driven Facilitator/supervisor- Supervisor-driven Small-group

driven maintainer/operator-

driven (i.e. self-

sustaining

Production focus All departments All employees Autonomous small

Selected begin improvement use TPM groups implement

operators in pilot activities concepts activities

area work on Establish Early problem

improvement standardization detection/solving

plan

Maintenance Maintenance Training in Reducing

focus organizes to support maintenance equipment lifetime

Selected plant-wide projects skills for costs

maintainers and planned operators and

work with pilot maintenance maintainers

team

Management Stimulating interest, Encouraging Striving for world

focus managing resources teamwork, class performance

Policies and training and skill

structure to development

support long-

term

commitment