Page 172 - Tandem Techniques

P. 172

Page 155

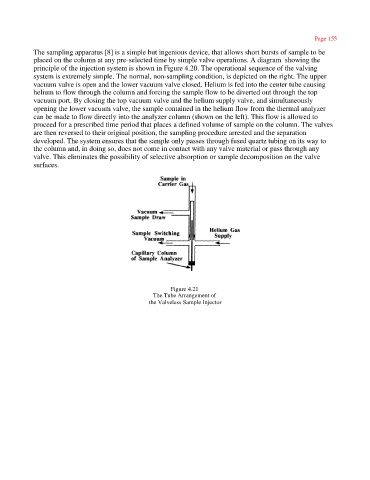

The sampling apparatus [8] is a simple but ingenious device, that allows short bursts of sample to be

placed on the column at any pre-selected time by simple valve operations. A diagram showing the

principle of the injection system is shown in Figure 4.20. The operational sequence of the valving

system is extremely simple. The normal, non-sampling condition, is depicted on the right. The upper

vacuum valve is open and the lower vacuum valve closed. Helium is fed into the center tube causing

helium to flow through the column and forcing the sample flow to be diverted out through the top

vacuum port. By closing the top vacuum valve and the helium supply valve, and simultaneously

opening the lower vacuum valve, the sample contained in the helium flow from the thermal analyzer

can be made to flow directly into the analyzer column (shown on the left). This flow is allowed to

proceed for a prescribed time period that places a defined volume of sample on the column. The valves

are then reversed to their original position, the sampling procedure arrested and the separation

developed. The system ensures that the sample only passes through fused quartz tubing on its way to

the column and, in doing so, does not come in contact with any valve material or pass through any

valve. This eliminates the possibility of selective absorption or sample decomposition on the valve

surfaces.

Figure 4.21

The Tube Arrangement of

the Valveless Sample Injector