Page 362 - The Engineering Guide to LEED-New Construction Sustainable Construction for Engineers

P. 362

A S y s t e m a t i c V i e w o f G r e e n a n d M i n i m u m P r o g r a m Re q u i r e m e n t s 323

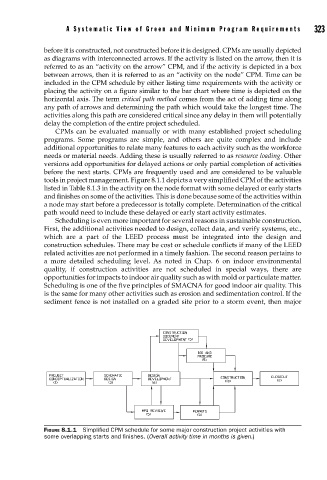

before it is constructed, not constructed before it is designed. CPMs are usually depicted

as diagrams with interconnected arrows. If the activity is listed on the arrow, then it is

referred to as an “activity on the arrow” CPM, and if the activity is depicted in a box

between arrows, then it is referred to as an “activity on the node” CPM. Time can be

included in the CPM schedule by either listing time requirements with the activity or

placing the activity on a figure similar to the bar chart where time is depicted on the

horizontal axis. The term critical path method comes from the act of adding time along

any path of arrows and determining the path which would take the longest time. The

activities along this path are considered critical since any delay in them will potentially

delay the completion of the entire project scheduled.

CPMs can be evaluated manually or with many established project scheduling

programs. Some programs are simple, and others are quite complex and include

additional opportunities to relate many features to each activity such as the workforce

needs or material needs. Adding these is usually referred to as resource loading. Other

versions add opportunities for delayed actions or only partial completion of activities

before the next starts. CPMs are frequently used and are considered to be valuable

tools in project management. Figure 8.1.1 depicts a very simplified CPM of the activities

listed in Table 8.1.3 in the activity on the node format with some delayed or early starts

and finishes on some of the activities. This is done because some of the activities within

a node may start before a predecessor is totally complete. Determination of the critical

path would need to include these delayed or early start activity estimates.

Scheduling is even more important for several reasons in sustainable construction.

First, the additional activities needed to design, collect data, and verify systems, etc.,

which are a part of the LEED process must be integrated into the design and

construction schedules. There may be cost or schedule conflicts if many of the LEED

related activities are not performed in a timely fashion. The second reason pertains to

a more detailed scheduling level. As noted in Chap. 6 on indoor environmental

quality, if construction activities are not scheduled in special ways, there are

opportunities for impacts to indoor air quality such as with mold or particulate matter.

Scheduling is one of the five principles of SMACNA for good indoor air quality. This

is the same for many other activities such as erosion and sedimentation control. If the

sediment fence is not installed on a graded site prior to a storm event, then major

FIGURE 8.1.1 Simplifi ed CPM schedule for some major construction project activities with

some overlapping starts and fi nishes. (Overall activity time in months is given.)