Page 460 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 460

446 A p p e n d i x D S i m u l a t e d C e r t i f i c a t i o n E x a m Q u e s t i o n s 447

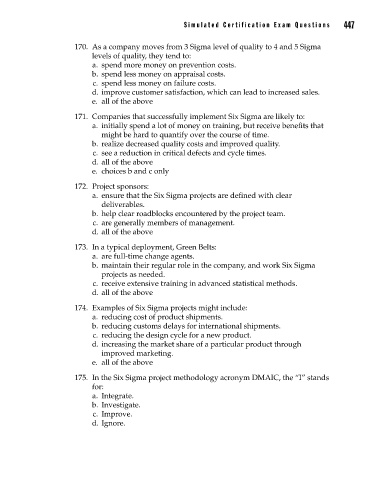

170. As a company moves from 3 Sigma level of quality to 4 and 5 Sigma

levels of quality, they tend to:

a. spend more money on prevention costs.

b. spend less money on appraisal costs.

c. spend less money on failure costs.

d. improve customer satisfaction, which can lead to increased sales.

e. all of the above

171. Companies that successfully implement Six Sigma are likely to:

a. initially spend a lot of money on training, but receive benefits that

might be hard to quantify over the course of time.

b. realize decreased quality costs and improved quality.

c. see a reduction in critical defects and cycle times.

d. all of the above

e. choices b and c only

172. Project sponsors:

a. ensure that the Six Sigma projects are defined with clear

deliverables.

b. help clear roadblocks encountered by the project team.

c. are generally members of management.

d. all of the above

173. In a typical deployment, Green Belts:

a. are full-time change agents.

b. maintain their regular role in the company, and work Six Sigma

projects as needed.

c. receive extensive training in advanced statistical methods.

d. all of the above

174. Examples of Six Sigma projects might include:

a. reducing cost of product shipments.

b. reducing customs delays for international shipments.

c. reducing the design cycle for a new product.

d. increasing the market share of a particular product through

improved marketing.

e. all of the above

175. In the Six Sigma project methodology acronym DMAIC, the “I” stands

for:

a. Integrate.

b. Investigate.

c. Improve.

d. Ignore.

21_Pyzdek_AppD_Ch21_p413-454.indd 447 11/9/12 5:33 PM