Page 41 - The Jet Engine

P. 41

Compressors

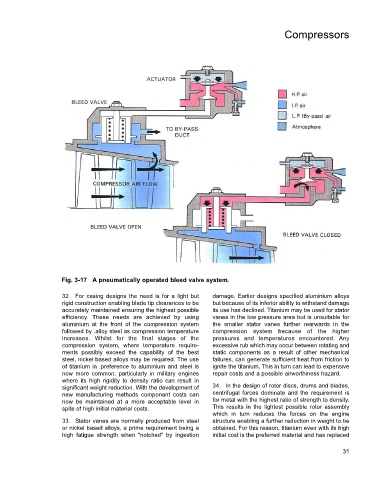

Fig. 3-17 A pneumatically operated bleed valve system.

32. For casing designs the need is for a light but damage. Earlier designs specified aluminium alloys

rigid construction enabling blade tip clearances to be but because of its inferior ability to withstand damage

accurately maintained ensuring the highest possible its use has declined. Titanium may be used for stator

efficiency. These needs are achieved by using vanes in the low pressure area but is unsuitable for

aluminium at the front of the compression system the smaller stator vanes further rearwards in the

followed by .alloy steel as compression temperature compression system because of the higher

increases. Whilst for the final stages of the pressures and temperatures encountered. Any

compression system, where temperature require- excessive rub which may occur between rotating and

ments possibly exceed the capability of the best static components as a result of other mechanical

steel, nickel based alloys may be required. The use failures, can generate sufficient heat from friction to

of titanium in .preference to aluminium and steel is ignite the titanium. This in turn can lead to expensive

now more common; particularly in military engines repair costs and a possible airworthiness hazard.

where its high rigidity to density ratio can result in

significant weight reduction. With the development of 34. In the design of rotor discs, drums and blades,

new manufacturing methods component costs can centrifugal forces dominate and the requirement is

now be maintained at a more acceptable level in for metal with the highest ratio of strength to density.

spite of high initial material costs. This results in the lightest possible rotor assembly

which in turn reduces the forces on the engine

33. Stator vanes are normally produced from steel structure enabling a further reduction in weight to be

or nickel based alloys, a prime requirement being a obtained. For this reason, titanium even with its high

high fatigue strength when "notched" by ingestion initial cost is the preferred material and has replaced

31