Page 39 - The Jet Engine

P. 39

Compressors

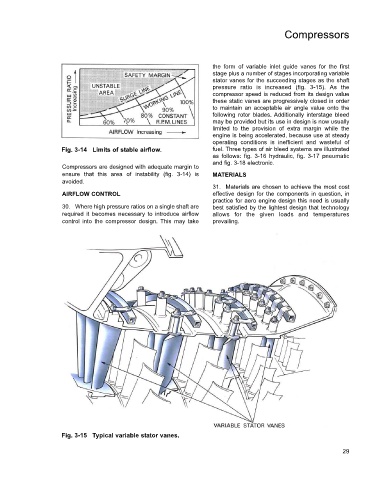

the form of variable inlet guide vanes for the first

stage plus a number of stages incorporating variable

stator vanes for the succeeding stages as the shaft

pressure ratio is increased (fig. 3-15). As the

compressor speed is reduced from its design value

these static vanes are progressively closed in order

to maintain an acceptable air angle value onto the

following rotor blades. Additionally interstage bleed

may be provided but its use in design is now usually

limited to the provision of extra margin while the

engine is being accelerated, because use at steady

operating conditions is inefficient and wasteful of

Fig. 3-14 Limits of stable airflow. fuel. Three types of air bleed systems are illustrated

as follows: fig. 3-16 hydraulic, fig. 3-17 pneumatic

and fig. 3-18 electronic.

Compressors are designed with adequate margin to

ensure that this area of instability (fig. 3-14) is MATERIALS

avoided.

31. Materials are chosen to achieve the most cost

AIRFLOW CONTROL effective design for the components in question, in

practice for aero engine design this need is usually

30. Where high pressure ratios on a single shaft are best satisfied by the lightest design that technology

required it becomes necessary to introduce airflow allows for the given loads and temperatures

control into the compressor design. This may take prevailing.

Fig. 3-15 Typical variable stator vanes.

29