Page 42 - The Jet Engine

P. 42

Compressors

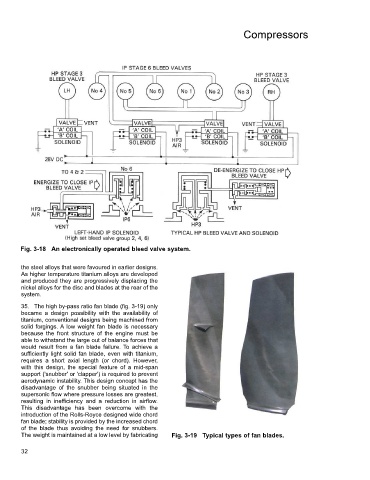

Fig. 3-18 An electronically operated bleed valve system.

the steel alloys that were favoured in earlier designs.

As higher temperature titanium alloys are developed

and produced they are progressively displacing the

nickel alloys for the disc and blades at the rear of the

system.

35. The high by-pass ratio fan blade (fig. 3-19) only

became a design possibility with the availability of

titanium, conventional designs being machined from

solid forgings. A low weight fan blade is necessary

because the front structure of the engine must be

able to withstand the large out of balance forces that

would result from a fan blade failure. To achieve a

sufficiently light solid fan blade, even with titanium,

requires a short axial length (or chord). However,

with this design, the special feature of a mid-span

support ('snubber' or 'clapper') is required to prevent

aerodynamic instability. This design concept has the

disadvantage of the snubber being situated in the

supersonic flow where pressure losses are greatest,

resulting in inefficiency and a reduction in airflow.

This disadvantage has been overcome with the

introduction of the Rolls-Royce designed wide chord

fan blade; stability is provided by the increased chord

of the blade thus avoiding the need for snubbers.

The weight is maintained at a low level by fabricating Fig. 3-19 Typical types of fan blades.

32