Page 38 - The Jet Engine

P. 38

Compressors

OPERATING CONDITIONS

28. Each stage of a multi-stage compressor

possesses certain airflow characteristics that are

dissimilar from those of its neighbour; thus to design

a workable and efficient compressor, the characteris-

tics of each stage must be carefully matched. This is

a relatively simple process to implement for one set

of conditions (design mass flow, pressure ratio and

rotational speed), but is much more difficult when

reasonable matching is to be retained with the

compressor operating over a wide range of

conditions such as an aircraft engine encounters.

29. If the operating conditions imposed upon the

compressor blade departs too far from the design

intention, breakdown of airflow and/or aerodynami-

cally induced vibration will occur. These phenomena

may take one of two forms; the blades may stall

because the angle of incidence of the air relative to

the blade is too high (positive incidence stall) or too

low (negative incidence stall). The former is a front

stage problem at low speeds and the latter usually

affects the rear stages at high speed, either can lead

to blade vibration which can induce rapid destruction.

If the engine demands a pressure rise from the

compressor, which is higher than the blading can

sustain, 'surge' occurs. In this case there is an instan-

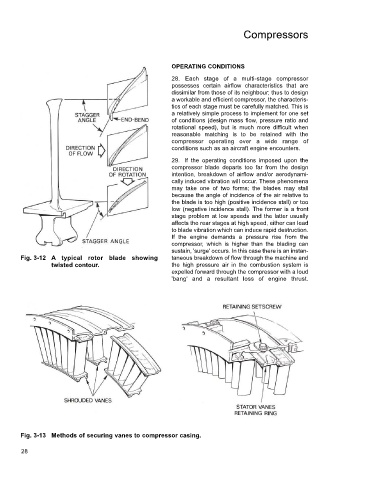

Fig. 3-12 A typical rotor blade showing taneous breakdown of flow through the machine and

twisted contour. the high pressure air in the combustion system is

expelled forward through the compressor with a loud

'bang' and a resultant loss of engine thrust.

Fig. 3-13 Methods of securing vanes to compressor casing.

28