Page 137 -

P. 137

The Practical Pumping Handbook LIIIIIIIIIIIIIIIIIII ....... iiiiiiiiiiiiiiiiii ............... iiiiiiiii11117711 ............ ~iiiii ::iiii::+~+ ~ +

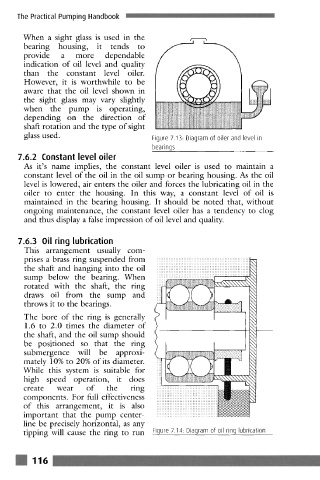

When a sight glass is used in the '-I I'

bearing housing, it tends to

provide a more dependable

indication of oil level and quality

than the constant level oiler.

However, it is worthwhile to be

aware that the oil level shown in

the sight glass may vary slightly

when the pump is operating,

depending on the direction of i+++i+i+!++i++++++++++++

shaft rotation and the type of sight l iii i ii +ii iii ii iiiil

glass used. Figure 7.13: Diagram of oiler and level in

bearings

7.6.2 Constant level oiler

As it's name implies, the constant level oiler is used to maintain a

constant level of the oil in the oil sump or bearing housing. As the oil

level is lowered, air enters the oiler and forces the lubricating oil in the

oiler to enter the housing. In this way, a constant level of oil is

maintained in the bearing housing. It should be noted that, without

ongoing maintenance, the constant level oiler has a tendency to clog

and thus display a false impression of oil level and quality.

7.6.3 Oil ring lubrication

This arrangement usually com-

prises a brass ring suspended from ::::::::::::::::::::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::::::::::::::::::::

the shaft and hanging into the oil ::::::::::::::::::::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::::::::::::::::::::

sump below the bearing. When :::::::::::::::::::::::::::::::::: ......................

rotated with the shaft, the ring

draws oil from the sump and

throws it to the bearings.

The bore of the ring is generally

1.6 to 2.0 times the diameter of

the shaft, and the oil sump should

be positioned so that the ring

submergence will be approxi-

mately 10% to 20% of its diameter.

While this system is suitable for

high speed operation, it does

create wear of the ring

:::::::::::::::::::::::::::::::::::::

components. For full effectiveness .....................................

:::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::

of this arrangement, it is also ::::::::::::::::::::::::::::::::::::

....................................

....................................

important that the pump center- ::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::

line be precisely horizontal, as any

tipping will cause the ring to run Figure 7.14: Diagram of oil ring lubrication

m 116 ._~ ................ ...+_ ,, -++ . . . . . l ................................ I ......................... it .............................. : ....... o,+