Page 77 -

P. 77

The Practical Pumping Handbook ~ iiiiii:

Therefore when Cavitation occurs in a pump, there are only two

possible solutions:

9 Decrease the NPSH Required, or

9 Increase the NPSH Available.

In exploring possible cures for cavitation, it is interesting to note that

(unless there has been a major selection or design flaw) most pumps

cavitate because there is a pressure differential between the NPSHA and

the NPSHR of less than a few feet. Consequently it is seldom necessary

to make a major change to eliminate the problem.

4.4.1 NPSH Required by the pump

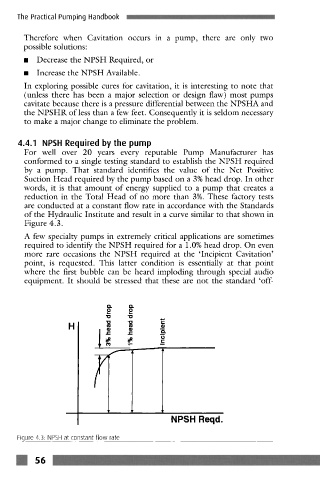

For well over 20 years every reputable Pump Manufacturer has

conformed to a single testing standard to establish the NPSH required

by a pump. That standard identifies the value of the Net Positive

Suction Head required by the pump based on a 3% head drop. In other

words, it is that amount of energy supplied to a pump that creates a

reduction in the Total Head of no more than 3%. These factory tests

are conducted at a constant flow rate in accordance with the Standards

of the Hydraulic Institute and result in a curve similar to that shown in

Figure 4.3.

A few specialty pumps in extremely critical applications are sometimes

required to identify the NPSH required for a 1.0% head drop. On even

more rare occasions the NPSH required at the 'Incipient Cavitation'

point, is requested. This latter condition is essentially at that point

where the first bubble can be heard imploding through special audio

equipment. It should be stressed that these are not the standard 'off-

o. 1~.

O O

9 'o "113

H "o 113 r

m

m

1-.. (,- o ~ El.

1 ~ ~ 0 r

NPSH Reqd.

Figure 4.3. NPSH at constant fl0w rate