Page 75 -

P. 75

The Practical Pumping Handbook .........................................................................................................

relatively familiar. They are a unique rumbling/rattling noise, and high

vibration levels. Closer inspection will also reveal pitting damage to the

impeller and a slight reduction in the Total Head being developed by

the pump. In order to consistently avoid or cure these problems, it is

important to understand what cavitation really is and what causes it in a

centrifugal pump.

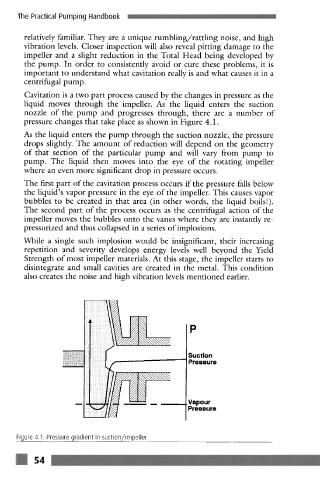

Cavitation is a two part process caused by the changes in pressure as the

liquid moves through the impeller. As the liquid enters the suction

nozzle of the pump and progresses through, there are a number of

pressure changes that take place as shown in Figure 4.1.

As the liquid enters the pump through the suction nozzle, the pressure

drops slightly. The amount of reduction will depend on the geometry

of that section of the particular pump and will vary from pump to

pump. The liquid then moves into the eye of the rotating impeller

where an even more significant drop in pressure occurs.

The first part of the cavitation process occurs if the pressure falls below

the liquid's vapor pressure in the eye of the impeller. This causes vapor

bubbles to be created in that area (in other words, the liquid boils!).

The second part of the process occurs as the centrifugal action of the

impeller moves the bubbles onto the vanes where they are instantly re-

pressurized and thus collapsed in a series of implosions.

While a single such implosion would be insignificant, their increasing

repetition and severity develops energy levels well beyond the Yield

Strength of most impeller materials. At this stage, the impeller starts to

disintegrate and small cavities arc created in the metal. This condition

also creates the noise and high vibration levels mentioned earlier.

P

x

Suction

Preseure

Vapour

Pressure

Figure 4.1 Pressure gradient in suction/impeller

m s4