Page 150 - The Toyota Way Fieldbook

P. 150

Chapter 6. Establish Standardized Processes and Procedures 127

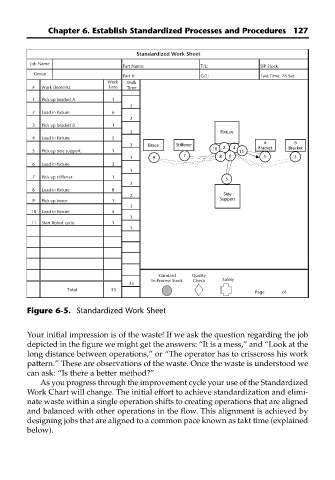

Standardized Work Sheet

Job Name

Part Name: T/L: SIP Stock:

Group

Part #: G/L: Takt Time: 76 Sec

Work Walk

# Work Elements Time Time

1 Pick up bracket A 1

2

2 Load in fixture 6

2

3 Pick up bracket B 1

3 Fixture

4 Load in fixture 5

A B

3 Brace Stiffener

5 Pick up side support 1 10 2 4 11 Bracket Bracket

1 9 7 8 6 1 3

6 Load in fixture 3

1

7 Pick up stiffener 1

5

2

8 Load in fixture 8

2 Side

9 Pick up brace 1 Support

3

10 Load in fixture 5

3

11 Start Robot cycle 1

1

Standard Quality

In-Process Stock Check Safety

23

Total 33

Page of

Figure 6-5. Standardized Work Sheet

Your initial impression is of the waste! If we ask the question regarding the job

depicted in the figure we might get the answers: “It is a mess,” and “Look at the

long distance between operations,” or “The operator has to crisscross his work

pattern.” These are observations of the waste. Once the waste is understood we

can ask: “Is there a better method?”

As you progress through the improvement cycle your use of the Standardized

Work Chart will change. The initial effort to achieve standardization and elimi-

nate waste within a single operation shifts to creating operations that are aligned

and balanced with other operations in the flow. This alignment is achieved by

designing jobs that are aligned to a common pace known as takt time (explained

below).