Page 172 - The Tribology Handbook

P. 172

B3 Gears

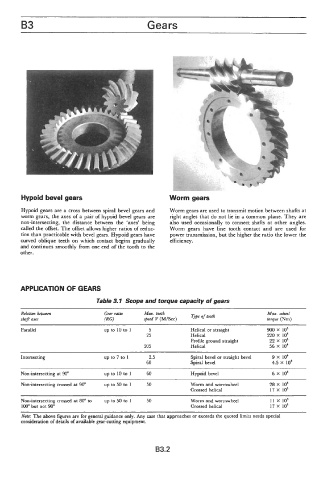

Hypoid bevel gears Worm gears

Hypoid gears are a cross between spiral bevel gears and Worm gears are used to transmit motion between shafts at

worm gears, the axes of a pair of hypoid bevel gears are right angles that do not lie in a common plane. They are

non-intersecting, the distance between the 'axes' being also used occasionally to connect shafts at other angles.

called the offset. The offset allows higher ratios of reduc- Worm gears have line tooth contact and are used for

tion than practicable with bevel gears. Hypoid gears have power transmission, but the higher the ratio the lower the

curved oblique teeth on which contact begins gradually efficiency.

and continues smoothly from one end of the tooth to the

other.

APPLICATION OF GEARS

Table 3.1 Scope and torque capacity of gears

Relation between Max. tooth Max. wheel

shaft axes speed V (M/Sec) Type of tooth torque (Nm)

Parallel up to 10 to 1 5 Helical or straight goo x io4

25 Helical 220 x io4

Profile ground straight 22 x io4

205 Helical 56 x io4

Intersecting up to 7 to 1 2.5 Spiral bevel or straight bevel 9 x io4

60 Spiral bevel 4.5 x io4

Non-intersecting at 90" up to 10 to 1 60 Hypoid bevel 6 X lo4

Non-intersecting crossed at 90" up to 50 to 1 50 Worm and wormwheel 28 x io4

Crossed helical 17 x io4

Non-intersecting crossed at 80" to up to 50 to 1 50 Worm and wormwheel 11 x io4

100" but not 90" Crossed helical 17 x io4

~~

Note: The above figures are for general guidance only. Any case that approaches or exceeds the quoted limits needs special

consideration of details of available gear-cutting equipment.

B3.2