Page 169 - The Tribology Handbook

P. 169

Roller chain drives B2

LUBRICATION METHODS

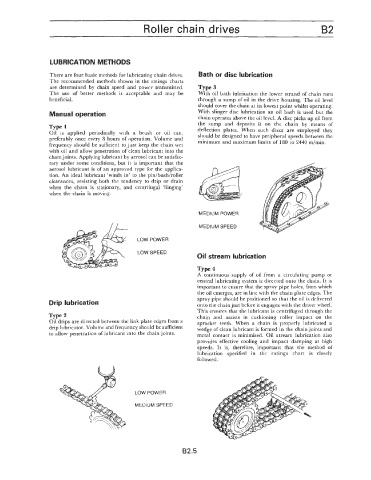

There are four basic methods for lubricating chain drives. Bath or disc lubrication

The recommended methods shown in the ratings charts

are determined by chain speed and power transmitted. Type 3

The use of better methods is acceptable and may be With oil bath lubrication the lower strand of chain runs

beneficial. through a sump of oil in the drive housing. The oil level

should cover the chain at its lowest point whilst operating.

Manual operation With slinger disc lubrication an oil bath is used but the

chain operates above the oil level. A disc picks up oil from

the sump and deposits it on the chain by means of

Type 1 deflection plates. When such discs are employed they

Oil is applied periodically with a brush or oil can, should be designed to have peripheral speeds between the

preferably once every 8 hours of operation. Volume and minimum and maximum limits of 180 to 2440 m/min.

frequency should be sufficient to just keep the chain wet

with oil and a.llow penetration of clean lubricant into the

chain joints. Applying lubricant by aerosol can be satisfac-

tory under some conditions, but it is important that the

aerosol lubricant is of an approved type for the applica-

tion. An ideal lubricant ‘winds in’ to the pin/bush/roller

clearances, resisting both the tendency to drip or drain

when the chain is stationary, and centrifugal ‘flinging’

when the chain is moving.

MEDIUM POWER

MEDIUM SPEED

LOW POWER

LOW SPEED

Oil stream lubrication

Type 4

A continuous supply of oil from a circulating pump or

central lubricating system is directed onto the chain. It is

important to ensure that the spray pipe holes, from which

the oil emerges, are in line with the chain plate edges. The

spray pipe should be positioned so that the oil is delivered

Drip lubrication onto the chain just before it engages with the driver wheel.

This ensures that the lubricant is centrifuged through the

Type 2 chain and assists in cushioning roller impact on the

Oil drips are directed between the link plate edges from a sprocket teeth, When a chain is properly lubricated a

drip lubricator. Volume and frequency should be sufficient wedge of clean lubricant is formed in the chain joints and

to allow penetration of lubricant into the chain joints. metal contact is rninimised. Oil stream lubrication also

provides effective cooling and impact damping at high

speeds. It is, therefore, important that the method of

lubrication specified in the ratings chart is closely

followed.

LOW POWER

MEDIUM SPEED

€32.5