Page 171 - The Tribology Handbook

P. 171

Gears B3

GEAR TYPES

C aight bevel gears

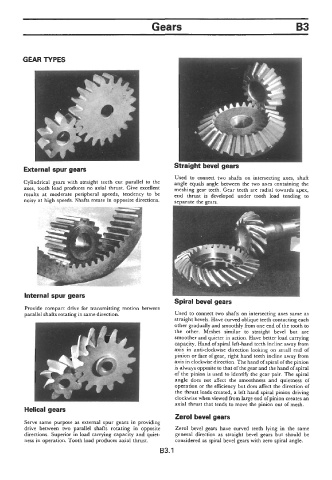

External spur gears

Used to connect two shafts on intersecting axes, shaft

Cylindrical gears with straight teeth cut parallel to the angle equals angle between the two axes containing the

axes, tooth load produces no axial thrust. Give excellent meshing gear teeth. Gear teeth are radial towards apex,

results at moderate peripheral speeds, tendency to be end thrust is developed under tooth load tending to

noisy at high speeds. Shafts rotate in opposite directions. separate the gears.

Internal spur gears

Spiral bevel gears

Provide compact drive for transmitting motion between

parallel shafts rotating in same direction. Used to connect two shafts on intersecting axes same as

straight bevels. Have curved oblique teeth contacting each

other gradually and smoothly from one end of the tooth to

the other. Meshes similar to straight bevel but are

smoother and quieter in action. Have better load carrying

capacity. Hand of spiral left-hand teeth incline away from

axis in anti-clockwise direction looking on small end of

pinion or face of gear, right hand teeth incline away from

axis in clockwise direction. The hand of spiral of the pinion

is always opposite to that of the gear and the hand of spiral

of the pinion is used to identify the gear pair. The spiral

angle does not affect the smoothness and quietness of

operation or the efficiency but does affect the direction of

the thrust loads created, a left hand spiral pinion driving

clockwise when viewed from large end of pinion creates an

axial thrust that tends to move the pinion out of mesh.

Helical gears

Zerol bevel gears

Serve same purpose as external spur gears in providing

drive between two parallel shafts rotating in opposite Zerol bevel gears have curved teeth lying in the same

directions. Superior in load carrying capacity and quiet- general direction as straight bevel gears but should be

ness in operation. Tooth load produces axial thrust. considered as spiral bevel gears with zero spiral angle.

B3.1