Page 168 - The Tribology Handbook

P. 168

B2 Roller chain drives

DRIVER SPROCKET SPEEDS rev/min

mmm

660 500 340

495 375 255

;L' 132 1W 66

z 99 75 51

2

c 6 6 M 3 4

9 50 38 26

330 250 170

X 29 7 22.5 15.3

26.4 20.0 13.6

5 23.1 17.5 11.9

4 19.8 12.5 10.2

15.0

8.5

16.5

3 13.2 10.0 6.8

5 9.9 7.5 5.1

s

E 66 5.0 3.4

5.0

2.6

3.8

k

3 3.30 2.50 1.70

2.97 2.25 1.53

3 2.M 2.W 1.36

- 231 175 119

% 198 150 102

161 125 085

$ 132 100 068

5 0.99 0.75 0.51

2 0.66 0.50 034

50

' 0.38 0.26

0

0.33 0.25 0.17

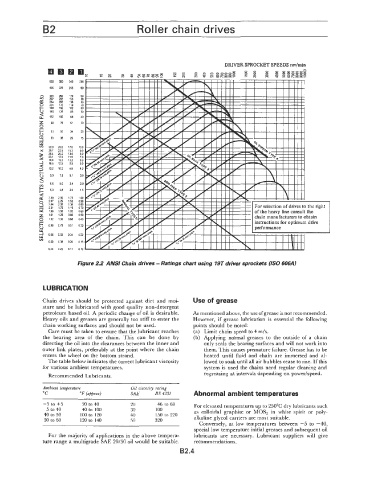

Figure 2.2 ANSI Chain drives - Ratings chart using 19T driver sprockets (IS0 606A)

LUBRICATION

Chain drives should be protected against dirt and moi- Use of grease

sture and be lubricated with good quality non-detergent

petroleum based oil. A periodic change of oil is desirable. As mentioned above, the use ofgrease is not recommended.

Heavy oils and greases are generally too stiff to enter the However, if grease lubrication is essential the following

chain working surfaces and should not be used. points should be noted:

Care must be taken to ensure that the lubricant reaches (a) Limit chain speed to 4 m/s.

the bearing area of the chain. This can be done by (b) Applying normal greases to the outside of a chain

directing the oil into the clearances between the inner and only seals the bearing surfaces and will not work into

outer link plates, preferably at the point where the chain them. This causes premature failure. Grease has to be

enters the wheel on the bottom strand. heated until fluid and chain are immersed and al-

The table below indicates the correct lubricant viscosity lowed to soak until all air bubbles cease to rise. If this

for various ambient temperatures. system is used the chains need regular cleaning and

Recommended Lubricants. regreasing at intervals depending on power/speed.

Ambient temfierature Oil viscosity rating

"C "F (afifirox) SAE BS 4231 Abnormal ambient temperatures

-5 to +5 20 to 40 20 46 to 68 For elevated temperatures up to 250°C dry lubricants such

5 to 40 40 to 100 30 100 as colloidal graphite or MOS2 in white spirit or poly-

40 to 50 100 to 120 40 150 to 220

50 to 60 120 to 140 50 320 alkaline glycol carriers are most suitable.

Conversely, at low temperatures between -5 to -40,

special low temperature initial greases and subsequent oil

For the majority of applications in the above tempera- lubricants are necessary. Lubricant suppliers will give

ture range a multigrade SAE 20/50 oil would be suitable. recommendations.

B2.4