Page 164 - The Tribology Handbook

P. 164

61 Belt drives

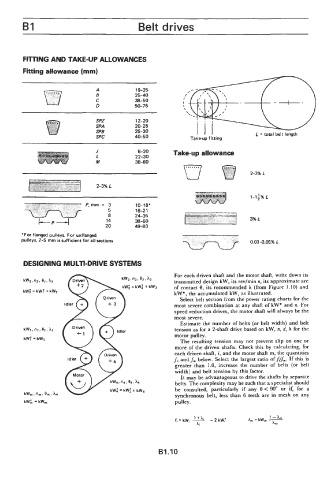

FllTlNG AND TAKE-UP ALLOWANCES

Fiiing allowance (mm)

A 19-25

E 25-40

C 38-50

0 50-75

SPZ 12-20

SPA 20-25

SPB 25-30 I l l

SPC 40-50 Take-up fitting L = total belt length

J 8-20 Take-up allowance

L 22-30

M 38-80

2-3% L

2-3% L

P,mm = 3 10-16'

5 16-21

8 24-35

14 38-60

L P J 20 49-80

"For flanged pulleys. For unflanged

pulleys, 2-5 mm issufficient for all sections

0.03-0.05% L

DESIGNING MULTI-DRIVE SYSTEMS

For each driven shaft and the motor shaft, write down its

transmitted design kW, its rev/min R, its approximate arc

= kW; + kW3 of contact 8, its recommended A (from Figure 1.10) and

kW*, the accumulated kW, as illustrated.

Select belt section from the power rating charts for the

most severe combination at any shaft of kW* and n. For

speed reduction drives, the motor shaft will always be the

most severe.

Estimate the number of belts (or belt width) and belt

kWl .nlI el, hl tension as for a 2-shaft drive based on kW, n, d, A for the

motor pulley.

kW; = kW1

The resulting tension may not prevent slip on one or

more of the driven shafts. Check this by calculating, for

each driven shaft, i, and the motor shaft m, the quantities

fi and fm below. Select the largest ratio of fifm. If this is

greater than 1.0, increase the number of belts (or belt

width) and belt tension by this factor.

It may be advantageous to drive the shafts by separate

belts. The complexity may be such that a specialist should

be consulted, particularly if any 8 < 90" or if, for a

kW, , n, . em, hrn

synchronous belt, less than 6 teeth are in mesh on any

kWL = kW, pulley.

91.10