Page 226 - The Tribology Handbook

P. 226

Capstans and drums B12

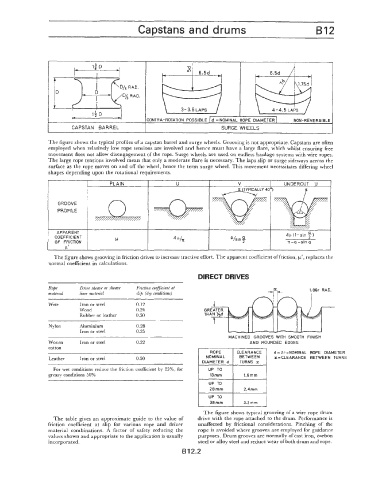

The figure shows the typical profiles of a capstan barrel and surge wheels. Grooving is not appropriate. Capstans are often

employed when relatively low rope tensions are involved and hence must have a large flare, which whilst ensuring free

movement does not allow disengagement of the rope. Surge wheels are used on endless haulage systems with wire ropes.

The large rope tensions involved mean that only a moderate flare is necessary. The laps slip or surge sideways across the

surface as the rope moves on and off the wheel, hence the term surge wheel. This movement necessitates differing wheel

shapes depending upon the rotational requirements.

GROOVE

PROFILE

APPARENT

COEFFICIENT

OF FRICTION

IL'

The figure shows grooving in friction drives to increase tractive effort. The apparent coefficient of friction, PI, replaces the

normal coefficient in calculations.

DIRECT DRIVES

Rope L)riue sheave or sheave Friction coefficient at 1.06r RAD.

material liner material slip (dry conditions) +=P-

Wire Iiron or steel 0.12

Wood 0.24

Rubber or leather 0.50

Nylon Aluminium 0.28

Iiron or steel 0.25

MACHINED GROOVES WITH SMOOTH FINISH

Woven Iiron or steel 0.22 AND ROUNDED EDGES

cotton

CLEARANCE d=2r=NOMINAL ROPE DIAMETER

Leather Iron or steel 0.50 ==CLEARANCE BETWEEN TURNS

~~

For wet conditions reduce the firiction coefficient by 25%, for

greasy conditions 50%

The figure shows typical grooving of a wire rope drum

The table gives an approximate guide to the value of drive with the rope attached to the drum. Performance is

friction coefficient at slip for various rope and driver unaffected by frictional considerations. Pinching of the

material combinations. A factor of safety reducing the rope is avoided where grooves are employed for guidance

values shown and appropriate to the application is usually purposes. Drum grooves are normally of cast iron, carbon

incorporated. steel or alloy steel and reduce wear of both drum and rope.

B 12.2