Page 350 - The Tribology Handbook

P. 350

C14 Total loss grease systems

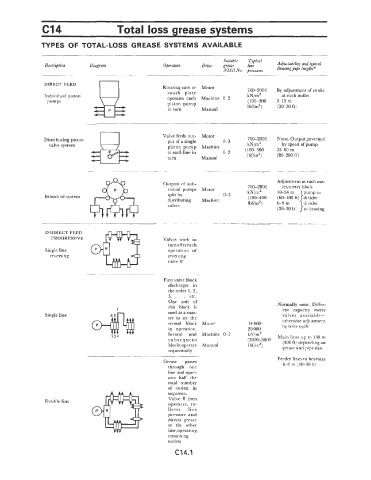

TYPES OF TOTAL-LOSS GREASE SYSTEMS AVAILABLE

Suitable Typical

Description Diagram Operation Drive grease line Adjustability and typical

~VLGI~V~. pressures limiting Pipe lengths*

DIRECT FEED

Rotating cam or Motor

swash plate 700-2000 By adjustment of stroke

Individual piston operates each Machine 0-2 kN/m2 at each outlet

pumps piston pump (100-300 9--15 m

in turn Manual Ibf/in2) (30-50 ft)

Valve feeds out- Motor

Distributing piston put of a single 0-3 700-2000 None. Output governed

valve system piston pump Machine kN/mZ by speed of pump

to each line in 0-2 (100-300 25-60 m

turn Manual Ibf/in2) (80-200 ft)

Outputs of indi- Adjustment at eachout-

let/meter block

vidual pumps Motor 700-2800 18-54 m pump to

kN/mZ

Branched system split by 0 -3 (100-400 (60-180 ft)}divider

distributing Machine

valves Ibf/in2) 6-9 m wider

(20-30 ft) }:o bearing

INDIRECT FEED

PROGRESSIVE Valves work in

turn after each

Single line operation of

reversing reversing

valve R

First valve block

discharges in

the order 1, 2,

3, . . .i etc.

One unit of

this block is Normally none. Differ-

1 ent capacity meter

Single line used as a mas- valves available-

ter to set the

second block Motor 14 000- otherwise adjustment

in operation. 20 000 by time cycle

Second and Machine 0-2 kN/rn2

subsequent ~2000-3000 Main lines up to 150 m

blocks operate Manual Ibf/in2) (500 ft) depending on

sequentially grease and pipe size.

Feeder lines to bearings

Grease passes

through one 6-9 m (20-30 ft)

line and oper-

ates half the

total number

of outlets in

sequence.

Double line Valve R then

operates, re-

lieves line

pressure and

directs grease

to the other

line, operating

remaining

outlets

C14.1