Page 351 - The Tribology Handbook

P. 351

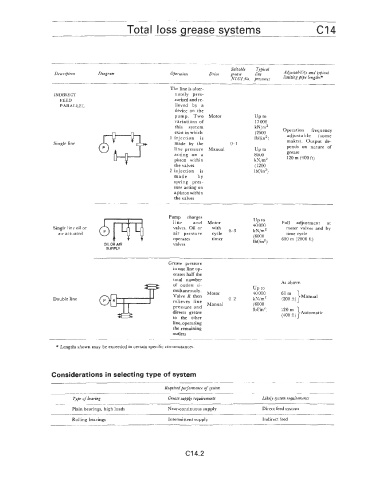

Total loss qrease svstems C14

The line is alter-

INDIRECT nately pres-

FEED surised and re-

PARALLEL lieved by a

device on the

pump. Two Motor up to

variations of 17 000

this system kN/mZ

exist in which (2500 Operation frequency

1 injection is Ibf/in2) adjustable (some

Single line made by the 9- 1 makes). Output de-

pends on nature of

line pressure Manual up to

acting on a ilo(lsr grease

piston within kN/m2 120 m (400 ft)

the valves (1200

2 injection is Ibf/in2)

made by

spring pres-

sure acting on

a piston within

the valves

Pump charges

line and Motor up Full adjustment at

Single line oil or valves. Oil or with 40 000 meter valves and by

air actuated air pressure cycle 0-3 kN/mZ time cycle

operates timer (6000 600 m (2000 ft)

OILOR AIR valves Ibf/in2)

SUPPLY

Grease pressure

in one line op-

erates half the

total number As above.

of outlets si- uD to

multaneously.

Valve R then Motor

Double line 0-2

relieves line Manual (6000 i

pressure and

directs grease

to the other

line, operating

the remaining

outlets

* Lengths shown may be exceeded in certain specific circumstances.

Considerations in selecting type of system

___

Required performance of system

~__~_~____ _____

Type of bearing Grease supply reyuirements Likely system requirements

___~~ ..____.._____.~

Plain bearings, high loads Near-continuous supply Direct feed system

_____~__ ___

Roiling bearings Intermittent supply Indirect feed

__-__-_____- ______

C14.2