Page 355 - The Tribology Handbook

P. 355

Total loss oil and fluid grease systems C15

GENERAL Multi-outlet - electric or pneumatic

Most total loss systems available from manufacturers are Operation. An electric or pneumatic motor drives cam-

now designed to deliver lubricants ranging from light oils operated pumping units positioned radially on the base of

to fluid greases of NLGI 000 consistency. the pump. The pump is cycled by an adjustable electronic

Fluid grease contains approximately 95% oil and has timer or by electrical impulses from the parent machine,

the advantage of being retained in the bearing longer than e.g. brake light operations on a commercial vehicle.

oil, thus reducing the quantity required whilst continuing Individual 4 mm OD nylon tubes deliver lubricant to

to operatle satisfactorily in most types of system. each bearing.

The main applications for total loss systems are for

chassis bearings on commercial vehicles, machine tools, Applications: Commercial vehicles, packaging machines

textile machinery and packaging plant. and conveyors.

Becausz of the small quantity of lubricant delivered by

these systems. they are not suitable for use where cooling Specification:

in addition to lubrication is required, e.g. large gear drives.

Fluid grease is rapidly growing in popularity except in Outlets: 1-60 (0.01-1.00 ml)

the machine tool industry where oil is preferred. Pressure: To 10 MN/m2

All automatic systems are controlled by electronic or Lubricants: 60 cSt oil to NLGI 000 grease (NLGI 2

electric adjustable timers, with the more sophisticated pneumatic).

products having the facility to operate from cumulated Failure warning: Pump operation by Light or visual move-

impulses from the parent machine. ment.

Individual lubricant supply to each bearing is fixed and Cost factor: Low (electric), Medium (pneumatic).

adjustment is, effected by changing the injector unit.

However, overall lubrication from the system is adjusted

by varying the interval time between pump cycles.

UNITS BEARINGS

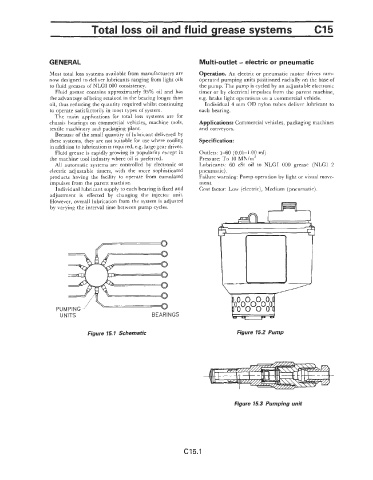

Figure 15.1 Schematic figure 15.2 Pump

Figure 75.3 Pumping unit

C15.1