Page 358 - The Tribology Handbook

P. 358

C15 Total loss oil and fluid grease systems

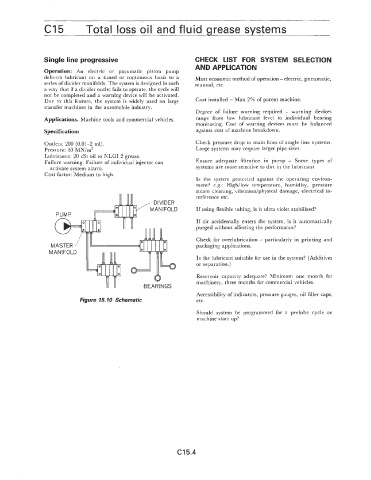

Single line progressive CHECK LIST FOR SYSTEM SELECTION

AND APPLICATION

Operation: An electric or pneumatic piston pump

delivers lubricant on a timed or continuous basis to a Most economic method of operation - electric, pneumatic,

series of divider manifolds. The system is designed in such manual. etc.

a way that if a divider outlet fails to operate, the cycle will

not be completed and a warning device will be activated.

Due to this feature, the system is widely used on large Cost installed - Max 2% of parent machine.

transfer machines in the automobile industry.

Degree of failure warning required - warning devices

Applications. Machine tools and commercial vehicles. range from low lubricant level to individual bearing

monitoring. Cost of warning devices must be balanced

Specification: against cost of machine breakdown.

Outlets: 200 (0.01-2 ml). Check pressure drop in main lines of single line systems.

Pressure: 10 MN/m2 Large systems may require larger pipe sizes.

Lubricants: 20 cSt oil to NLGI 2 grease.

Failure warning: Failure of individual injector can Ensure adequate filtration in pump - Some types of

activate system alarm. systems are more sensitive to dirt in the lubricant

Cost factor: Medium to high.

Is the system protected against the operating environ-

ment? e.g.: Highhow temperature, humidity, pressure

steam cleaning, vibration/physical damage, electrical in-

terference etc.

If using flexible tubing, is it ultra violet stabilised?

If air accidentally enters the system, is it automatically

purged without affecting the performance?

Check for overlubrication - particularly in printing and

packaging applications.

Is the lubricant suitable for use in the system? (Additives

or separation.)

Reservoir capacity adequate? Minimum one month for

machinery, three months for commercial vehicles.

Accessibility of indicators, pressure gauges, oil filler caps,

Figure 15.10 Schematic etc.

Should system be programmed for a prelube cycle on

machine start up?

C15.4