Page 359 - The Tribology Handbook

P. 359

Dip, splash systems C16

SPUR, BEVEL AND HELICAL GEARS

All gears, ex.cept very slow running ones, require complete enclosure. In general, gears dip into oil for twice tooth depth, to

provide sufficient splash for pinions, bearings, etc. and to reduce churning loss to a minimum.

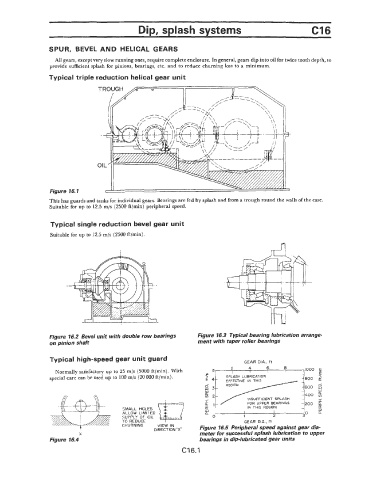

Typical triple reduction helical gear unit

Figure 76.1

This has guards and tanks for individual gears. Bearings are fed by splash and from a trough round the walls of the case.

Suitable for up to 12.5 m/s (2500 ftlmin) peripheral speed.

Typical single reduction bevel gear unit

Suitable for up to 12.5 m/s (2500 ftlmin).

Figure 16.2 Bevel unit with double row bearings Figure 16.3 Typical bearing lubrication arrange-

on pinion sharft ment with taper roller bearings

Typical high-speed gear unit guard GEAR DIA., ft

E

-.

Normally satisfactory up to 25 m/s (5000 ftlmin). With e 5 /

special care can be used up to 100 m/s (20 000 ftlmin). E 4- SPLASH LUBRICATION 800 g

EFFECTIVE IN THIS

SUPPLY OF OIL a a 2- INSUFFICIENT SPLASH i400 a

REGION

600

I'

-200 a

FOR UPPER BEARINGS

-

LL

a 1-

IN THIS REGION

L

SMALL HOLES

ALLOW LIMITED

a

TO REDUCE - ----- w I GEAR DIA., rn 1 -

CHURNING VIEW IN Figure 16.5 Peripheral speed against gear dia-

DIRECTION 'X'

x meter for successful splash lubrication to upper

Figure 76.4 bearings in dip-lubricated gear units

C16. 1