Page 376 - The Tribology Handbook

P. 376

c20 Design of storage tanks

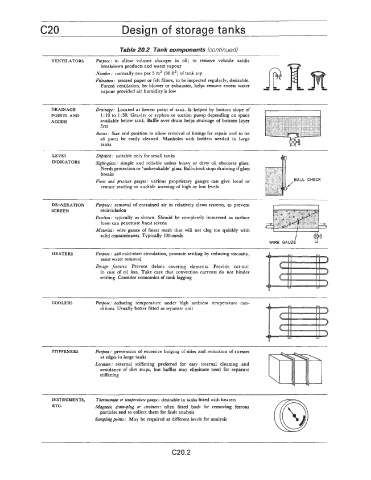

Table 20.2 Tank components (continued)

VENTILATORS Purpose: to allow volume changes in oil; to remove volatile acidic

breakdown products and water vapour

Number: normally one per 5 mz (50 ft’) of tank top

Filtration: treated paper or felt filters, to be inspected regularly, desirable. -

Forced ventilation, by blower or exhauster, helps remove excess water

vapour provided air humidity is low -I---

~~

DRAINAGE Drainage: Located at lowest point of tank. Is helped by bottom slope of

POINTS AND 1 : 10 to 1 :30. Gravity or syphon or suction pump depending on space

ACCESS available below tank. Baffle over drain helps drainage of bottom layer

first

Access: Size and position to allow removal of fittings for repair and to let

all parts be easily cleaned. Manholes with ladders needed in large

tanks

LEVEL Dipstick: suitable only for small tanks

INDICATORS Saght-glass: simple and reliable unless heavy or dirty oil obscures glass.

Needs protection or ‘unbreakable’ glass. Ball-check stops draining if glass

breaks

Float and pressure gauges: various proprietary gauges can give local or

CHECK

remote reading or audible warning of high or low levels JBALL

~

DE-AERATION Purpose: removal of entrained air in relatively clean systems, to prevent

SCREEN recirculation

Position: typically as shown. Should be completely immersed as surface

foam can penetrate finest screen

Matmal: wire gauze of finest mesh that will not clog too quickly with

solid contaminants. Typically 100-mesh

HEATERS Purpose: aid cold-start circulation, promote settling by reducing viscosity,

assist water removal

Design features: Prevent debris covering elements. Provide cut-out

in case of oil loss. Take care that convection currents do not hinder

settling. Consider economics of tank lagging

COOLERS Purpose: reducing temperature under high ambient temperature con-

ditions. Usually better fitted as separate unit

STIFFENERS Purpose: prevention of excessive bulging of sides and reduction of stresses

at edges in large tanks

Location: external stiffening preferred for easy internal cleaning and

avoidance of dirt traps, but baffles may eliminate need for separate

stiffening

INSTRUMENTS, Thermometer M temperature gauge: desirable in tanks fitted with heaters

ETC. Magnetic drain-plug or strainers: often fitted both for removing ferrous

particles and to collect them for fault analysis

Sampling points : May be required at different levels for analysis

c20.2