Page 375 - The Tribology Handbook

P. 375

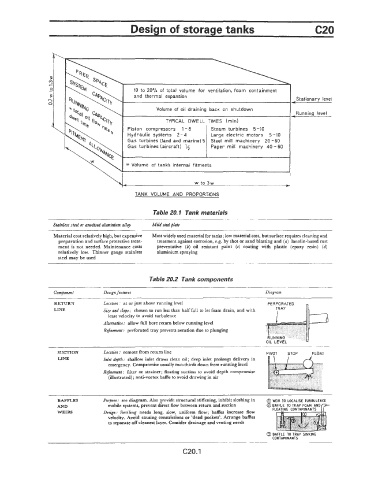

Design of storage tanks c20

Stationary level

Running level

Piston compressors 1 - 8 Steam turbines 5-10

Hydraulic systems 2-4 Large electric motors 5-10

Gas turbines [land and marine) 5 Steel mill machinery 20-60

Gas turbines (aircraft) ’/2 Paper mill machinery 40-60

= Volume of tank’s internal fitments

w to 3w =-

TANK VOLUME AND PROPORTIONS

Table 20. I Tank materials

Stainless steel or dised aluminium all9 Mild steel plate

Material cost relatively high, but expensive Most widely used material for tanks; low material cost, but surface requires cleaning and

preparation and surface protective treat- treatment against corrosion, e.g. by shot or sand blasting and (a) lanolin-based rust

ment is not needed. Maintenance costs preventative (b) oil resistant paint (c) coating with plastic (epoxy resin) (d)

relatively low. Thinner gauge stainless aluminium spraying

steel may be used

~~

Table 20.2 Tank components

Component Design Jecrtures Diagram

RETURN Locatton. at or just above running level PERFORATED

LINE &e and slope: chosen to run less than half full to let foam drain, and with

least velocity to avoid turbulence

Altemuh : allow full bore return below running level

Rcjincmmt: perforated tray prevents aeration due to plunging

SUCTION Location: remote from return line PfVOT STCP FLOAT

LINE Inlet dcptlr : shallow inlet draws clean oil ; deep inlet prolongs delivery in

emergency. Compromise usually two-thirds down from running level

Rejnmcnt: filter or strainer; floating suction to avoid depth compromise

(illustrated) ; anti-vortex baffle to avoid drawing in air

BAFFLES Purpose: see diagram. Also provide structural stiffening, inhibit sloshing in 0 WEIR TO LOCALISE TURBULENCE

AND mobile systems, prevent direct Row between return and suction @:

WEIRS Design: Settling needs long, slow, uniform flow; baffles increase flow

velocity. Avoid causing constrictions or ‘dead pockets’. Arrange baffles

to separate off cleanest layer. Consider drainage and venting needs

0 BAFFLE TO TRAP SINKING

CONTAMINANTS

c20.1