Page 371 - The Tribology Handbook

P. 371

Commissioning lubrication systems c19

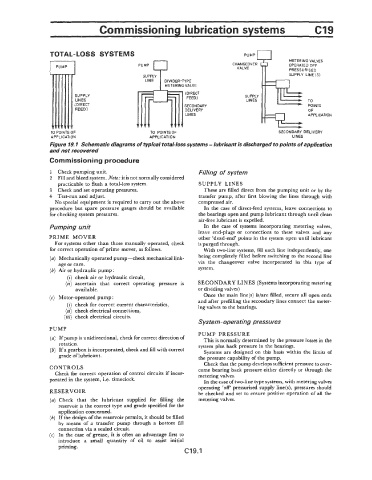

TOTAL-LOSS SYSTEMS PUMP

L ERING VALVES

CHANGEOVER

VALVE

YPE

VALVE

(DIRECT SUPPLY

FEED) LINES

SECONDARY

DELIVERY

LINES APPLICATION

TO POINTS OF TO POINTSOF SECONDARY DELIVERY

APPLICATION APPLICATION LINES

Figure 19. I Schematic diagrams of typical total-loss systems - lubricant is discharged to points of application

and not recalvered

Commissioning procedure

1 Check pumping unit. Filling of system

2 Fill and bleed system. Note: it is not normally considered

practicable to flush a total-loss system. SUPPLY LINES

3 Check andset operating pressures. These are filled direct from the pumping unit or by the

4 Test-run and adjust. transfer pump, after first blowing the lines through with

No special equipment is required to carry out the above compressed air.

procedure but spare pressure gauges should be available In the case of direct-feed systems, leave connections to

for checking system pressures. the bearings open and pump lubricant through until clean

air-free lubricant is expelled.

Pumping unit In the case of systems incorporating metering valves,

leave end-plugs or connections to these valves and any

PRIME MOVER other ‘dead-end’ points in the system open until lubricant

For systems other than those manually operated, check is purged through.

for correct operation of prime moves, as follows. With two-line systems, fill each line independently, one

(a) Mechanically operated pump-check mechanical link- being completely filled before switching to the second line

age or cam. via the changeover valve incorporated in this type of

(6) Air or hydraulic pump : system.

(i) check air or hydraulic circuit,

(ii) ascertain that correct operating pressure is SECONDARY LINES (Systems incorporating metering

available. or dividing valves)

Once the main line(s) islare filled, secure all open ends

(c) Motor-operated pump: and after prefilling the secondary lines connect the meter-

(i) check for correct current characteristics, ing valves to the bearings.

(ii) check electrical connections,

(iii) check electrical circuits.

System-operating pressures

PUMP

PUMP PRESSURE

(a) If pump is unidirectional, check for correct direction of This is normally determined by the pressure losses in the

rotation. system plus back pressure in the bearings.

(b) If a gearbox is incorporated, check and fill with correct Systems are designed on this basis within the limits of

grade of lubricant. the pressure capability of the pump.

Check that the pump develops sufficient pressure to over-

CONTROLS come bearing back pressure either directly or t

Check for correct operation of control circuits if incor- metering valves.

porated in the system, i.e. timeclock. In the case of two-line type systems, with metering valves

operating ‘off pressurised supply line(s), pressures should

RES ERVO I I;I be checked and set to ensure positive operation of all the

(a) Check that the lubricant supplied for filling the metering valves.

reservoir is the correct type and grade specified for the

application concerned.

(6) If the design of the reservoir permits, it should be filled

by means of a transfer pump through a bottom fill

connection via a sealed circuit.

(c) In the case of grease, it is often an advantage first to

introduce a small quantity of oil to assist initial

priming.

(219.1