Page 367 - The Tribology Handbook

P. 367

Ci rcu I at i o n systems C18

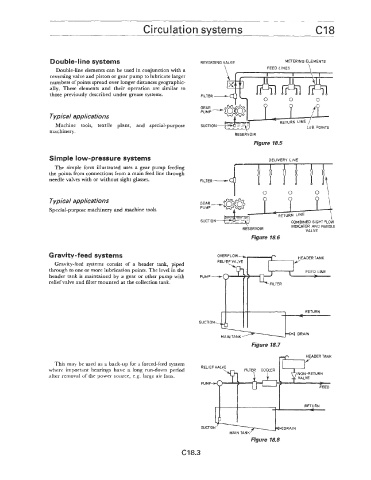

Double-line systems METERING ELEMENTS

Double-line elements can be used in conjunction with a

reversing valve and piston or gear pump to lubricate larger

numbers of points spread over longer distances geographic-

ally. These elements and their operation are similar to FILTER -

those previously described under grease systems.

Typical applications

Machine itools, textile plant, and special-purpose

machinery.

RESERVOIR

Figure 18.5

Simple low-pressure systems DELIVERY LINE

The simple form illustrated uses a gear pump feeding

the points from connections from a main feed line through

needle valves with or without sight glasses.

Typical applications

Special-purpose machinery and machine tools.

COMBINED SIGHT FLOW

INDICATOR AND NEEDLE

RESERVOIR

VALVE

Figure 18.6

Gravity-feed systems

Gravity-feed systems consist of a header tank, piped

through to one or more lubrication points. The level in the

header tank is maintained by a gear or other pump with

relief valve and filter mounted at the collection tank.

Figure 18.7

YER

This may be used as a back-up for a forced-feed system TANK

where important bearings have a long run-down period RELIEF’ tALVE f3LTEY

~n, COYLER

after removal of the power source, e.g. large air fans. . :TURN

PUM

RETURN

SUCTION DRAIN

MAIN TANK

Figure 18.8

C18.3