Page 154 - Welding of Aluminium and its Alloys

P. 154

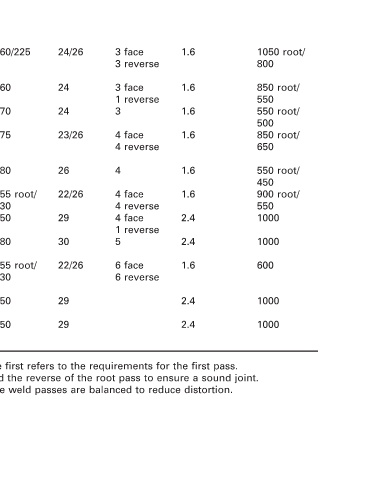

12.5 0.8/1.5 90 None 260/225 24/26 3 face 1.6 1050 root/

double- 3 reverse 800

V

2.5/1.5 60 Temporary 260 24 3 face 1.6 850 root/

single-V 1 reverse 550

4.5/nil 60 Permanent 270 24 3 1.6 550 root/

single-V 500

16 1.5/1.5 90 None 275 23/26 4 face 1.6 850 root/

double- 4 reverse 650

V

4.5/nil 60 Permanent 280 26 4 1.6 550 root/

single-V 450

20 1.5/1.5 90 None 255 root/ 22/26 4 face 1.6 900 root/

double-V 230 4 reverse 550

3/2.5 60 Temporary 350 29 4 face 2.4 1000

single-V 1 reverse

6/nil 60 Permanent 380 30 5 2.4 1000

single-V

25 1.5/1.5 90 None 255 root/ 22/26 6 face 1.6 600

double- 230 6 reverse

V

4/2.5 60 Temporary 350 29 2.4 1000

single-V

6/nil 60 Permanent 350 29 2.4 1000

single-V

1. Where two welding parameters are specified in one entry the first refers to the requirements for the first pass.

2. Where a reverse side weld is specified it is necessary to grind the reverse of the root pass to ensure a sound joint.

3. When making a double sided joint it is recommended that the weld passes are balanced to reduce distortion.