Page 155 - Welding of Aluminium and its Alloys

P. 155

138 The welding of aluminium and its alloys

Table 7.3 Suggested welding parameters – helium shielding, flat position, large

diameter wires

Thickness Root Included Current Voltage No. of Filler Travel

(mm) gap/ angle (A) (V) passes diam. speed

face (degrees) (mm) (mm/min)

(mm)

50 0/5 70/2 550 32 2 each 4.8 250

sided side

75 0/10 30 650 30 3 each 5.6 250

6mm side

root R

Wire Travel

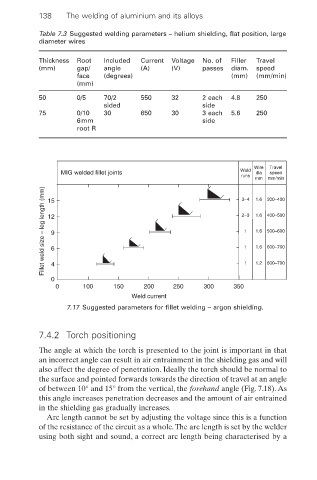

MIG welded fillet joints Weld dia speed

runs

mm 300–400

mm/min

Fillet weld size – leg length (mm) 12 9 6 2–3 1.6 400–500

1.6

3–4

15

500–600

1.6

1

1

600–700

1.6

0 4 1 1.2 600–700

0 100 150 200 250 300 350

Weld current

7.17 Suggested parameters for fillet welding – argon shielding.

7.4.2 Torch positioning

The angle at which the torch is presented to the joint is important in that

an incorrect angle can result in air entrainment in the shielding gas and will

also affect the degree of penetration. Ideally the torch should be normal to

the surface and pointed forwards towards the direction of travel at an angle

of between 10° and 15° from the vertical, the forehand angle (Fig. 7.18). As

this angle increases penetration decreases and the amount of air entrained

in the shielding gas gradually increases.

Arc length cannot be set by adjusting the voltage since this is a function

of the resistance of the circuit as a whole.The arc length is set by the welder

using both sight and sound, a correct arc length being characterised by a