Page 156 - Welding of Aluminium and its Alloys

P. 156

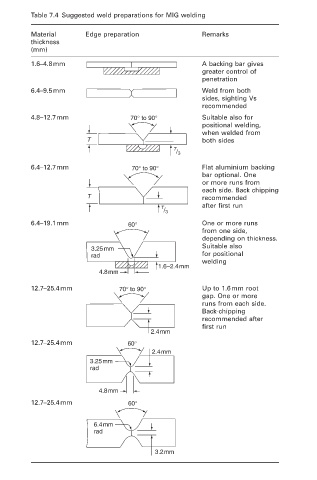

Table 7.4 Suggested weld preparations for MIG welding

Material Edge preparation Remarks

thickness

(mm)

1.6–4.8mm A backing bar gives

greater control of

penetration

6.4–9.5mm Weld from both

sides, sighting Vs

recommended

4.8–12.7mm 70° to 90° Suitable also for

positional welding,

when welded from

T both sides

T

/ 3

6.4–12.7mm 70° to 90° Flat aluminium backing

bar optional. One

or more runs from

each side. Back chipping

T recommended

T after first run

/ 3

6.4–19.1mm 60° One or more runs

from one side,

depending on thickness.

3.25mm Suitable also

rad for positional

welding

1.6–2.4mm

4.8mm

12.7–25.4mm 70° to 90° Up to 1.6mm root

gap. One or more

runs from each side.

Back-chipping

recommended after

first run

2.4mm

12.7–25.4mm 60°

2.4mm

3.25mm

rad

4.8mm

12.7–25.4mm 60°

6.4mm

rad

3.2mm